Isistimu yophindekiso nezimali (MIRAS)

Ukuvikela Kuhle, Ukungabibi Kuncinane, Iziphumo Ezifakelweyo Ngokuchanekileyo Ze-OEM/ODM.

- Ukuhlaziywa

- Imikhiqizo Econyiwe

Incazelo Yomkhiqizo

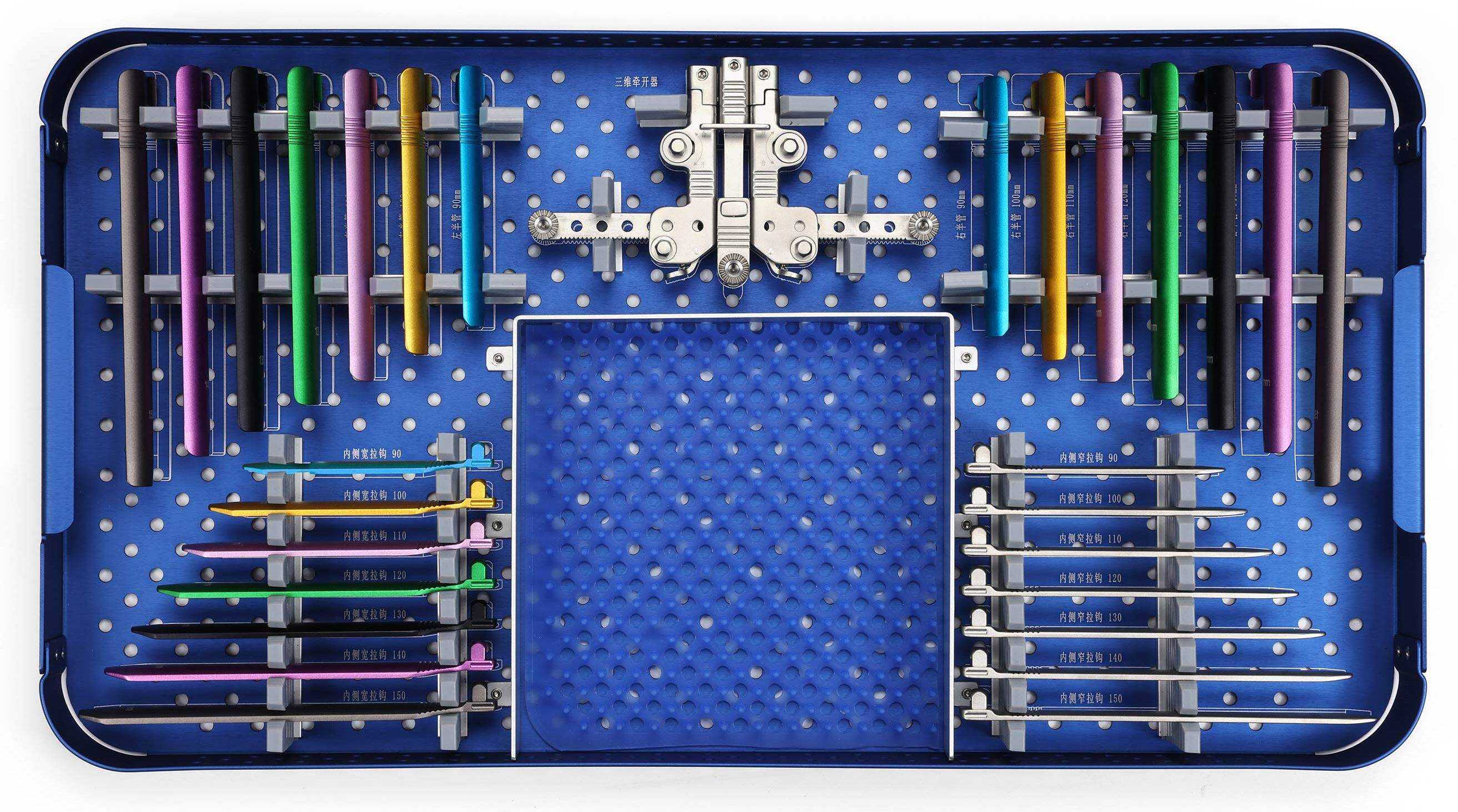

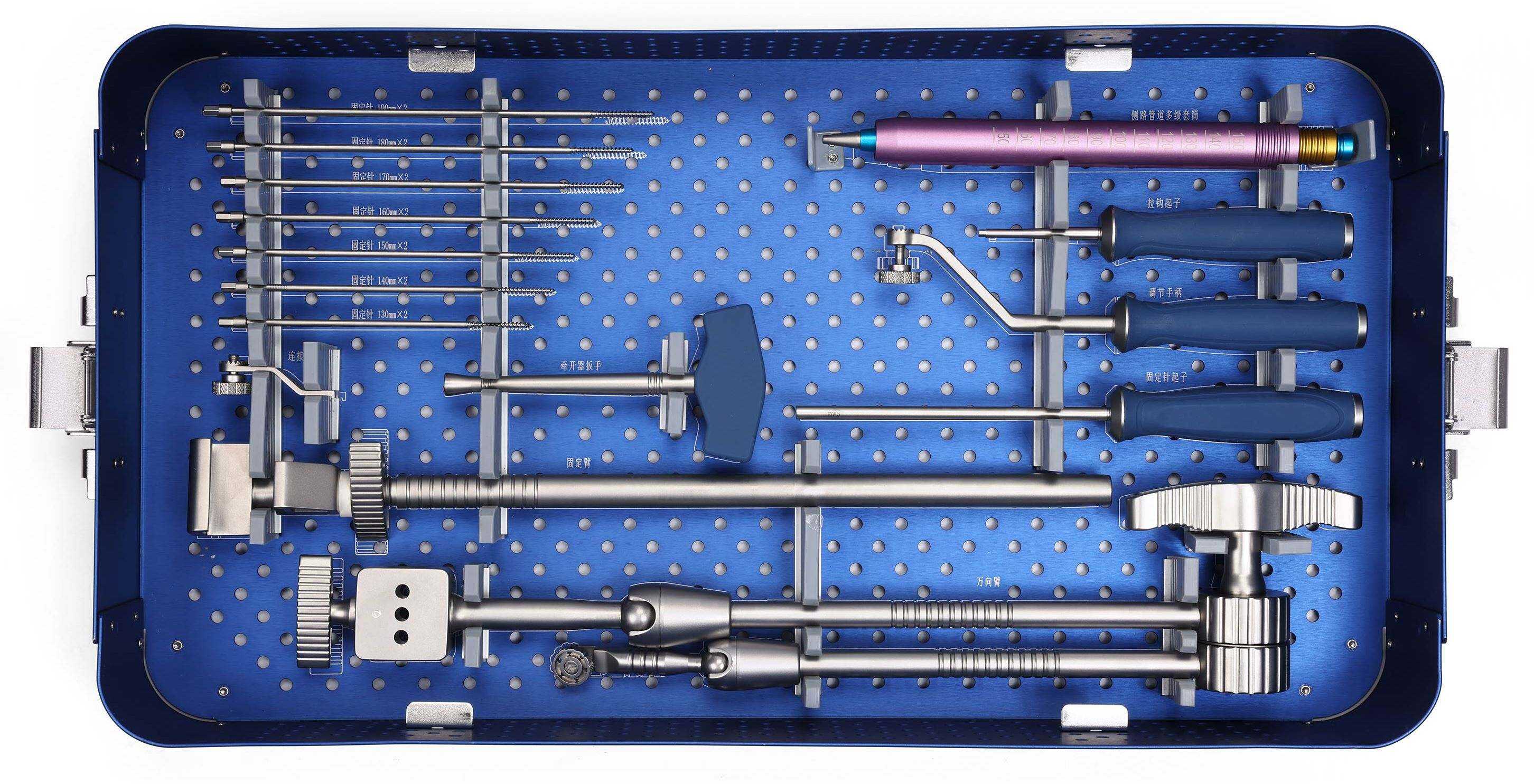

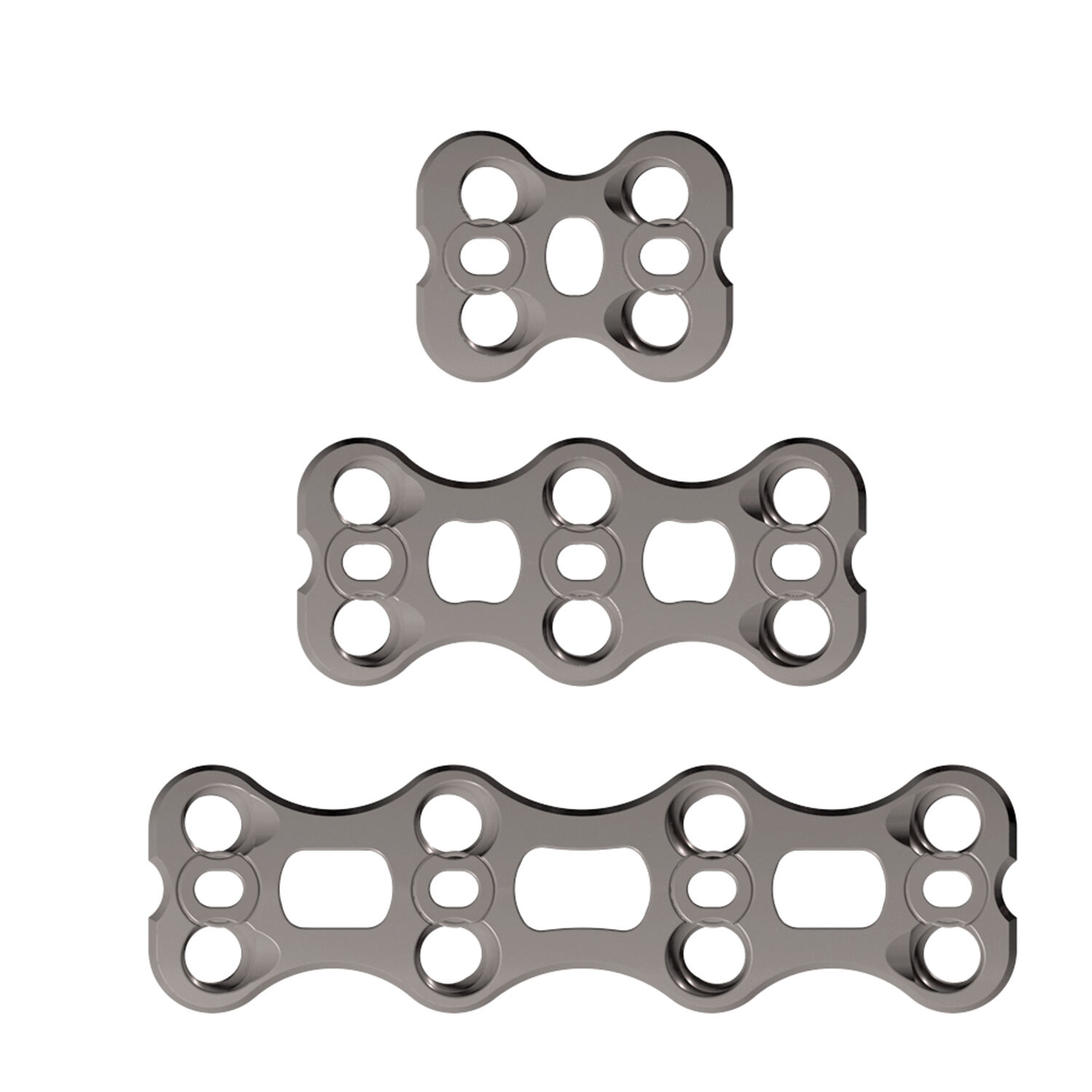

Isixhobo Sakhiwo Sokungena Kancinci (MIRAS) yisethi yezixhobo zokugcina esihlanganisiweyo esenzelwe ukugcina kancinci okuncinci kumgwa wasekunene namhla.

Iyakhaqha isiphazamo sesilisa esiphucukileyo nesibonakaliso sokugcina esihlawulwayo ngemithombo encinci, ibeka amagcini asebenzela ngokucophelela nokudibanisa ngapha kokuchitha kwisilisa.

Ngaphakathi Izixwayiso zeTaruk , sibhala futhi sikhula I-OEM/ODM izixhobo zokungena ezilungelwe ezilingana nexesha lakho lokufakwa, iintsikelelo zokugcina, neengcamango zobrand.

Iziphumo zethu zihlangana ne-engineering yomgangatho ophucukileyo kunye nenjongo engqongqo yokwenza kube lula ubunzima bokugcina kanye nokwenza kube lula umdla wokwakha.

Iimpawu Ezilungileyo Zentengo

● Ukugcinwa Okuncinane Nokwahlukaniswa – Izimboni zokuphakama ezimbi kanye nezandla ezifakiweyo zivumela ukungena ngendlela efihlakeleyo ngemva kwezincwadi eziphezulu kodwa kuzohlala yisivinini esihlukile.

● Ukubona Okuhle Kangaka – Amakhofu aqhubekisa ukuhlanganiswa kwegolide yesithuthi noma yegolide yendoscopy, okunikeza ubonakalayo oluhle ngaphakathi kwesimo se-operating.

● Uhlelo Lwesayensi Olufakwayo – Ububanzi, ubunjinga, kanye nobude bezimboni bengcono ngokulinganiselana nokuhlukahluka kwesimo sokusebenza noma kwezinhlelo zokulanda.

●Ukuphucumana Okungcono – Izinqubo zenzelwa ku-stainless steel enezimali ephakeme noma kwezilonda ze-titanium, ezinezindlela zokulinda izigaba eziningi zokucasha.

● Indlela Yokudala Ngokushesha – Izindawo zokudonsa kanye nezinhlelo zokugcina ezihlelekileyo zibeka phansi isikhathi sokulungiselela emkhumbini wokusebenta.

● Ukusebenzisa Okuvumelekile Kakhulu – Izixhandlana ezilula kanye nezehlakalo eziqhutshwa zivumela ukusebenza okungahlinzeki ngemva kwezinyathelo ezinde.

Ukulungisa Izinkinga Zokuthinta Isipha

Izinhlelo ezintsha zokuphatha kwezinyawo zidinga ukunciphisa izigubhu, ubude obuncane besabalalo, nokwakhiwa okufanayo kwezinhlelo yokuqhubeka.

Kodwa, izinhlelo eziningi zezixhobo ziyaphakama ngemibuzo:

● Ubunzima bokukhupha kakhulu phansi kwegcinekiso encane.

● Ukungenwa kokulayisha izixhobo ngezindlela zokufaka izimpini.

● Ukungabi nabo abaqashi base-OEM abakwazi ukuthuthukisa izinhlelo eziphathelene nezimali ezenziwayo.

Isistemu se-MIRAS yeTaruk isebenza ngokudla ngale mibuzo ngokunikeza ubukhona bomdaba, ukulingana okutholakala , kanye ubunikela obunembile kubamakhanda wezempilo ethola izisolve zonke ze-MIS.

Iinketho zeNkundla/Inkundla

Sisebenza njengeyona indawo yokwenza kumkani wakho, siphindelela izervice eziphambili zokuthutha okuchanekileyo:

● Ukukhokha Kwezenzo & Ukuphakama – Inkxaso ye-CAD/CAE yokuthi inkqubo yokuqeda iyaphuhlileyo kanye nokulungiswa kwegometry.

● Ukwenza Kwesibonelo Esibalaseleyo – Iziphrothotyphe ezakhiwe ngendlela ephrintiweyo nge-3D okanye ngendlela eyenzelwe ngokugcwalisa CNC, ezazange ziphume ngexesha elincinci.

● Izimoto Nezihlalo Ezichanekileyo – Isitshawa esikhanyisiweyo, itayitaniwe enziwe ngokwesithunywa, okanye ubushushu bephepha ngokulinganiso lomthengi.

● Iinketho Zokweba Igama Lekhomphini – Izilogo ezimakishiniwe ngelasere, ukulabela kwesithuthi esichanekileyo, iphakethe epholile/engapholanga, ukulungiswa kwe-IFU.

● Umbiko wokulawula – Izinhlobo zezinhlobo ezihlakilayo ezimbambene nezimfuno ze-ISO 13485.

● Amamodela ekuqashini – Kusukela emaqashini amancane abalulekile kuya kokuqasha okuphelele okuphinde kuthunyelwe endleleni yonke, ngezimali ezihlwayo.

Umsebenzi wonke ku-OEM/ODM uqala ngokubuka isakazelo, emva koko kuhlanjiswa ngokwenza umfanekiso, ukwakhiwa, nokubonga, futhi ukuba kukhona iqiniso eligcwele phakathi kwizinyathelo zonke.

Ingenzi YokuYenza Nezobuchwepheshe

Isiseko sokuqasha kukaTaruk sibamba amakhomphutha we-machining ane-axes amahlanu futhi nesikhungo sokuhlenga esiqhubekayo .

Silandela izinhloso eziphambene nezobuchwepheshe ngaphansi kwe ISO 13485 futhi sihlinze ubunikazi obugcwele bokunye kwinto yonke.

Ukuthembeka kwethikwalithi kwasemakhaya kufaka phakathi:

● Uhlaziywa kwe-metallography nezivikelo zomlando

● Ukukhokha kwezidingo ngaphansi kwe-CMM nokukhokha ngokujulile

● Ukuphazamisa, ukucwashelwa ngokungahambeki komsindo, nokubuyiselwa kwebhubhu

● Ukukhokha kuvuselelo nokuzivikela ngaphambi kokuthunyelwa

Ngokudibanisa umsebenzi wobuchwepheshe bokwenza izixhumanisi nokuphatha izikhathi ezimfutshane, i-Taruk ihlinzela ukuthi wonke umgca wokubamba uthole ukuthembeka, ukubuyiselwa, nokulandela izinhukumbano .

Inhloso Elingcono YeTaruk

● Zingu-20+ izinyanga zokuphuhlisa izixhobo zokugcina uhlelo olunye lwesingeni

● Ukudibaniswa kwebume belayini nesayilu yezinhlangano ngaphandle kwegumbi elinye

● Umqondo wasekhondlela we-R&D otholakala kusetentheni nasezinhlelweni ze-MIS

● Uhlaka olulungileyo ngokwezifundo zangempela nokwaziwa kokutholakala kwizinto

● Izinkampani eziqukethe izihlaku zezixwayiso zomhlaza e-EU, US, ne-APAC

Ubunzima baTaruk kukuba abize ukwenza okugcweleyo nokugcina okuphuculiweyo okunjalo , okusisekelisa izidzi zakho ekhathaziyweni elishintshayo kakhulu yemarkethi yesixwayiso esingaphansi sesixwayiso

Kungani Ukukhetha iTaruk Kuzo Rretractor Systems Yakho

● Umntu wokuxhumana oqukethwe kumqondo we-OEM/ODM wesixwayiso se-orthopedic

● Indlela enzima yokudala isibonelo kanye nokubuyisela kumqondo

● Ukugcina okunembala okuncane kodwa okuncane ngokuphelele

● Umgembelelo wezeji zolimi zihlanu kanye nendlela yokuxhumana eyangeni

● Inkinga yekhono: ukudizayina, ukuhlelwa, ukupakisha, izimali

Sihlinzekela ukuthi izinhlelo zakho zokuhlukanisa zifikelela abadokotela ngempela ngendlela ethembekile, esebenza kahle, futhi engaqondaniyo okufunwayo yisurgery yesishini esisha.

Umbuzo & Ukubamba

Uyathetha ukuthi ufunde kakhulu noma uphinde uhlele Isistimu yoku fikelela kumthwalo ophambili ngendlela ephambili ?

Ithimba lethekithi lethu libalulekile ekulungeniseni amathuba akho kanye nokunikela isinqumo sokuhlelwa okufanele kakhulu nezidingo zakho.

Thinta i-Taruk Medical Instruments namuhla — umkhuba wakho othembekile we-OEM/ODM wezinhlelo zezixhumanisi zesishini ezingaphansi komlando.