trauma bone plates and screws oem

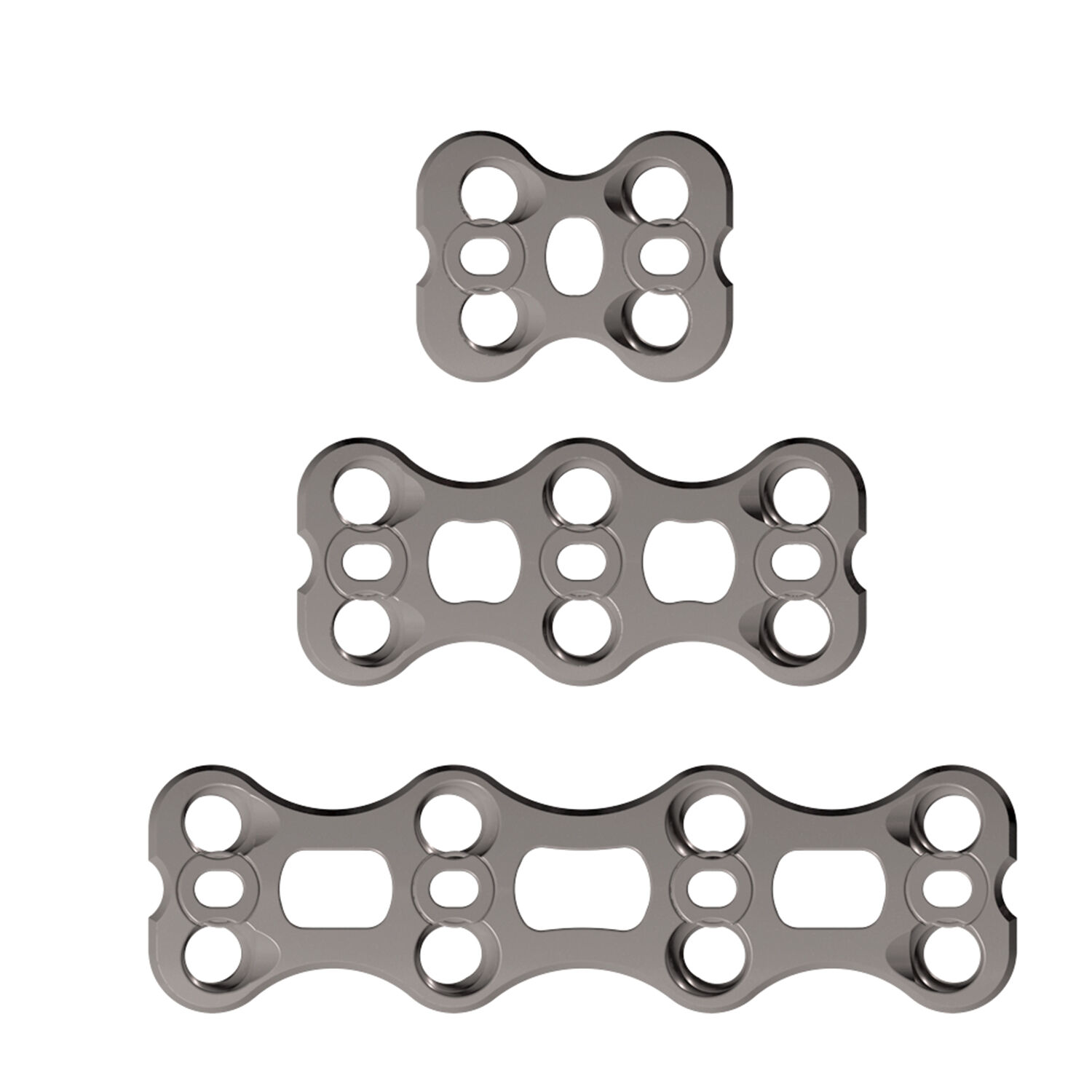

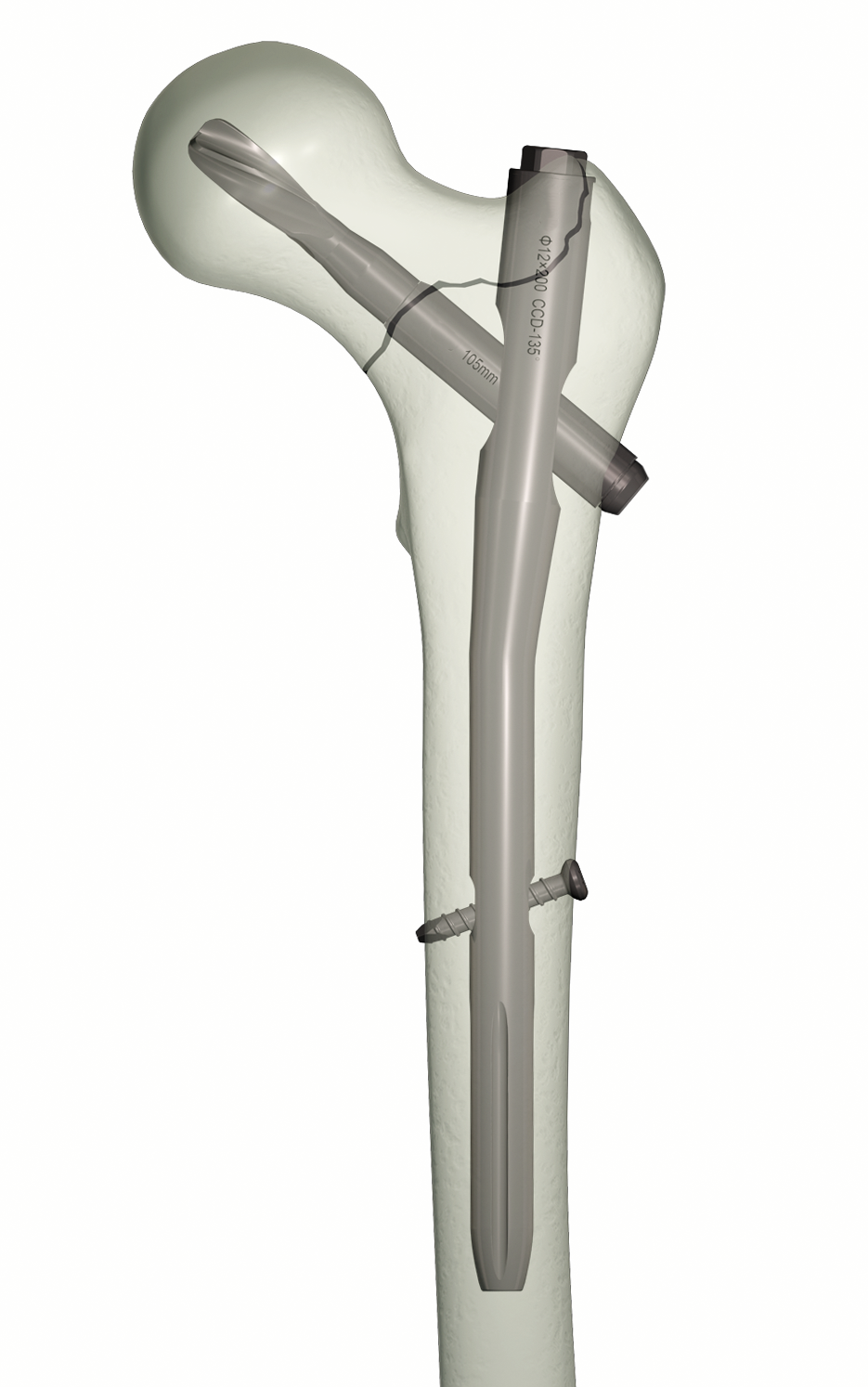

Trauma bone plates and screws OEM represents a critical advancement in orthopedic medical devices, offering customized solutions for fracture fixation and bone reconstruction. These precision-engineered implants are manufactured using medical-grade materials, primarily titanium alloys and stainless steel, ensuring optimal biocompatibility and durability. The plates and screws are designed to provide stable internal fixation, promoting proper bone alignment and facilitating natural healing processes. Each component undergoes rigorous quality control measures, including material testing, dimensional accuracy verification, and surface treatment validation. The manufacturing process incorporates state-of-the-art CNC machining technology, ensuring precise tolerances and consistent quality across production batches. These implants are available in various configurations to address different anatomical requirements and fracture patterns, including compression plates, reconstruction plates, and locking plates. The surface finish is optimized to reduce tissue irritation and enhance osseointegration, while the thread design of the screws ensures secure fixation and minimal tissue damage during insertion. The OEM service includes comprehensive documentation, sterility validation, and regulatory compliance support, making it a complete solution for medical device companies and healthcare providers.