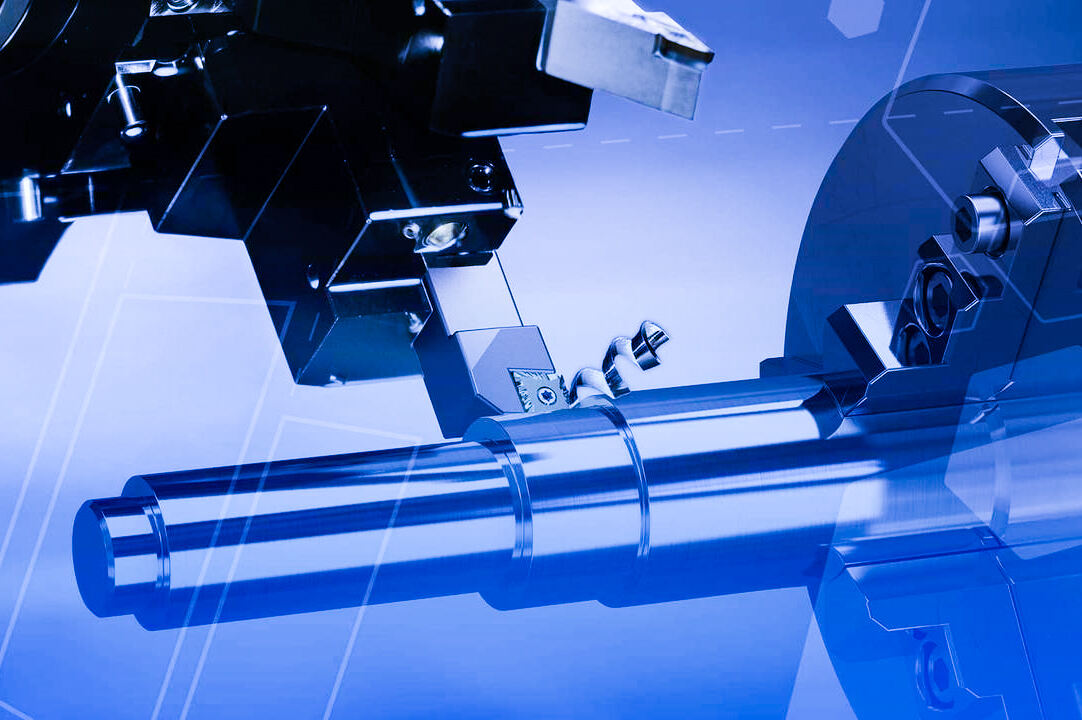

Swiss-type lathes have completely transformed traditional machining modes through three core technologies: multi-axis linkage, guide bushing support, and synchronized machining. The following explanation uses spinal products as a case in point.

1. Micron-level Precision Ensures Product Performance

- Dynamic Stability: The guide bushing clamps materials close to the cutting zone, suppressing vibration of slender shafts (amplitude < 5μm). This ensures spinal rod diameter tolerances are controlled within ±0.005mm and surface roughness Ra < 0.4μm.

- Multi-axis Collaborative Machining: The main spindle and sub-spindle rotate synchronously, combined with Y-axis live tools, enabling one-time completion of pedicle screw thread milling, head forming, and tail slotting with positional accuracy errors < ±0.01mm.

2. Full-process Automation Reduces Production Cycles

- Multi-process Integration: Fully automated production from bar feeding to finished product output. For example, in a company processing spinal rod systems, traditional processes required 8 hours per batch, while sliding head lathes only need 2.5 hours, increasing efficiency by 68%.

- Rapid Changeover Response: Realizing small-batch, multi-variety production switching through program calls instead of physical mold changes, reducing setup time from 4 hours to 20 minutes and improving equipment utilization by 40%.

3. Optimization of Cutting Parameters

Adopting high-speed cutting (spindle speed 10,000-12,000rpm) and minimum quantity lubrication (MQL) technology, titanium alloy machining efficiency is tripled while energy consumption is reduced by 25%.

4. Intelligent Production Reduces Hidden Costs

- Real-time Monitoring and Compensation: Integrating temperature and vibration sensors to dynamically adjust cutting parameters, reducing batch scrap due to tool wear and increasing yield from 85% to 98%.

- Predictive Maintenance: Through predictive maintenance systems (e.g., vibration analysis, oil monitoring), equipment failure rates are reduced by 60%, downtime is cut by 50%, and maintenance costs are lowered by 30%.

Hot News

Hot News