On November 25, an industrial procurement delegation from Anhui Province visited our company for an in-depth inspection and exchange. The delegation was warmly welcomed by General Manager Mr. Hong Xufeng and Sales Director Mr. Han Renwei, who accompanied the guests throughout the visit. The purpose of the tour was to strengthen mutual understanding, evaluate production capacity, and discuss potential large-scale cooperation opportunities in medical technology manufacturing.

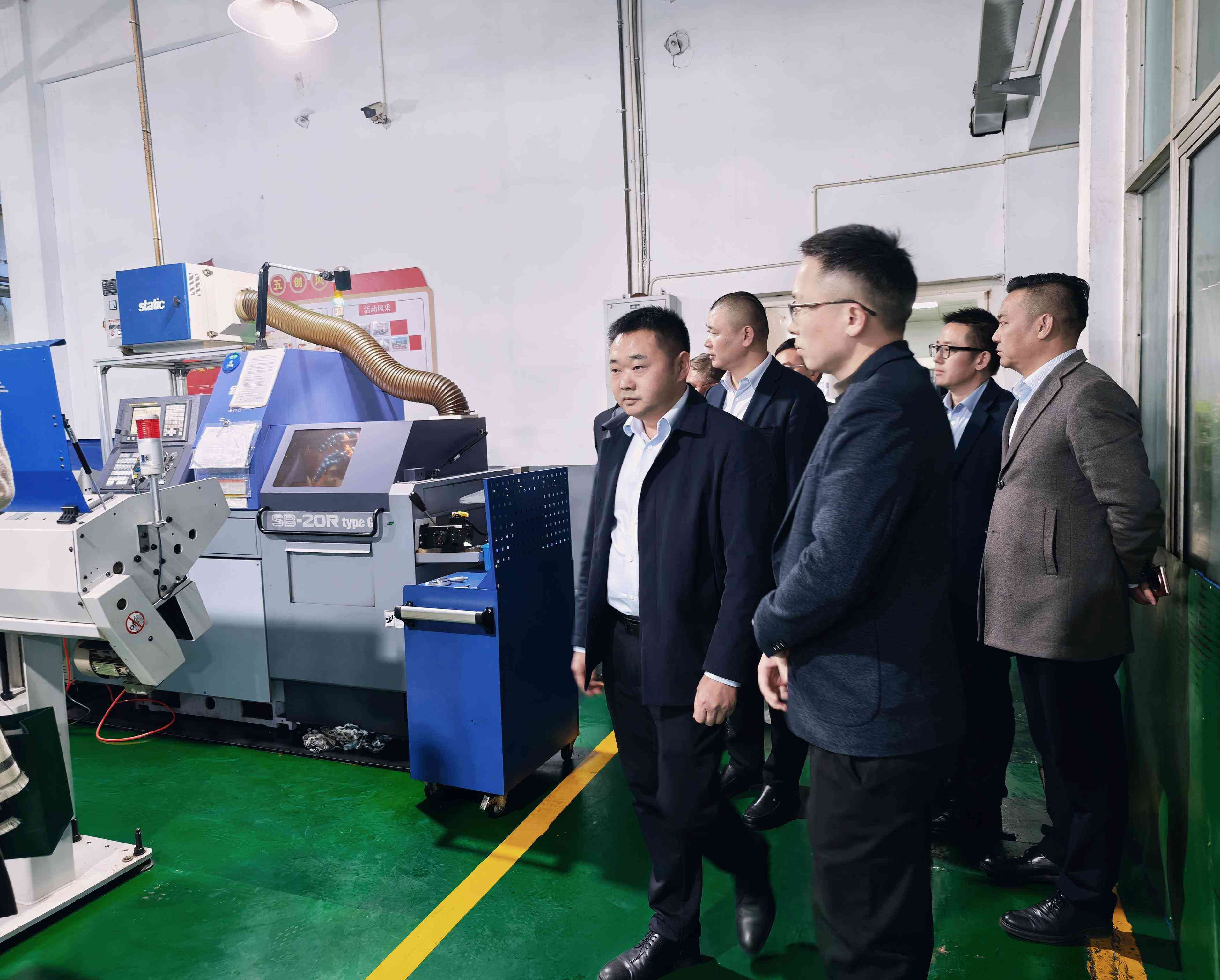

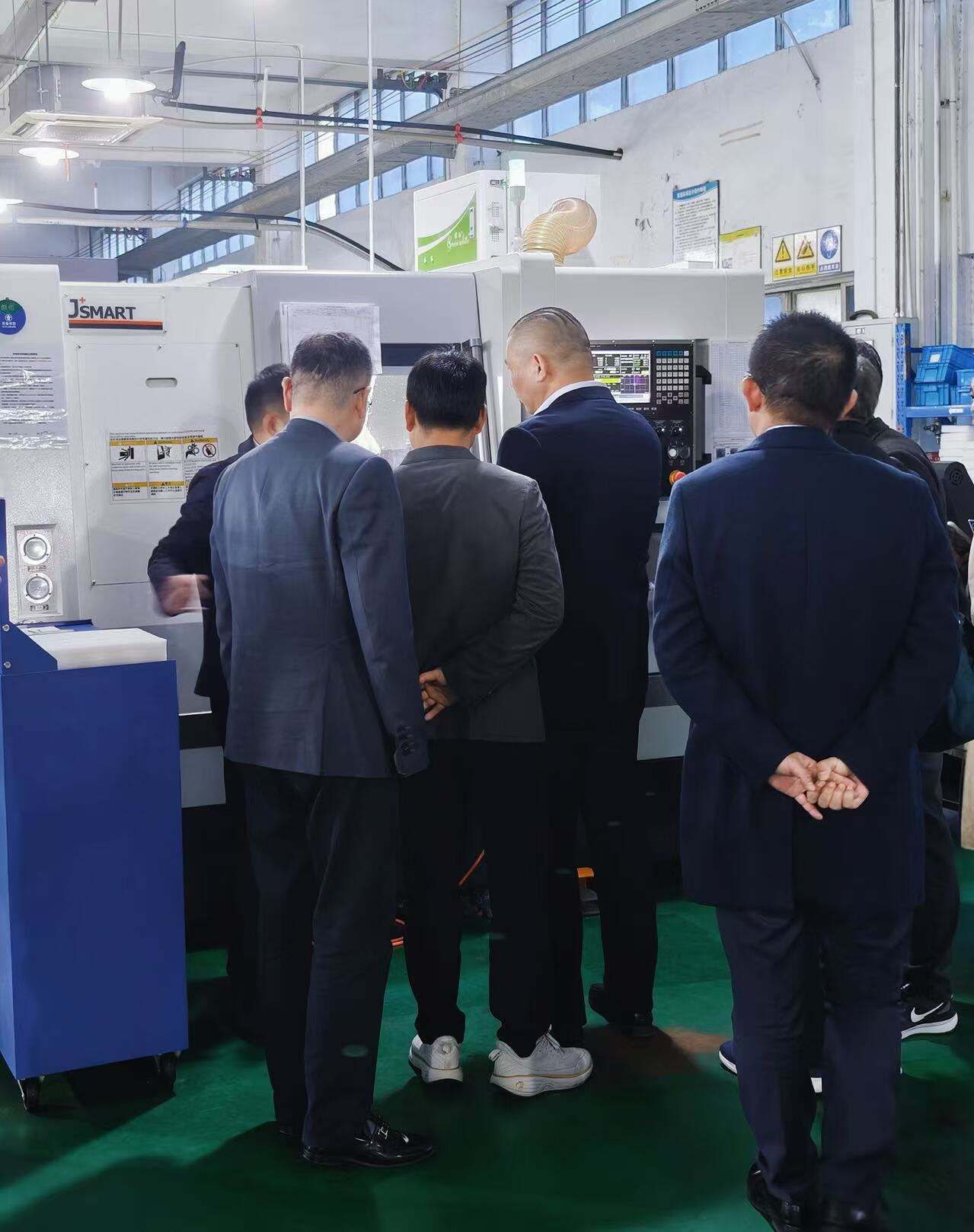

The visit began with a comprehensive walkthrough of our precision manufacturing workshop. As one of the core strengths of our company, the workshop integrates a full range of high-performance production equipment that ensures exceptional machining accuracy, production consistency, and international-level quality assurance. During the visit, General Manager Hong provided a detailed introduction to several of the company’s flagship systems:

● Japan-made Star sliding headstock automatic lathe units, known for high-precision micro-machining and stable performance.

● Mazak 5-axis machining centers, enabling complex structural processing and multi-angle cutting essential for advanced medical components.

● Germany FOBA laser marking systems, delivering traceability, corrosion-resistant permanent markings, and ultra-clear identification for global compliance.

● Germany ZEISS coordinate measuring machines, providing micron-level dimensional inspection and ensuring that every component meets strict international tolerances.

The delegation showed strong interest in the company’s production workflow, including raw material handling, tooling management, automated processing, and digital inspection procedures. They recognized the workshop’s modern layout, the emphasis on quality control, and the company’s consistent investment in world-class equipment.

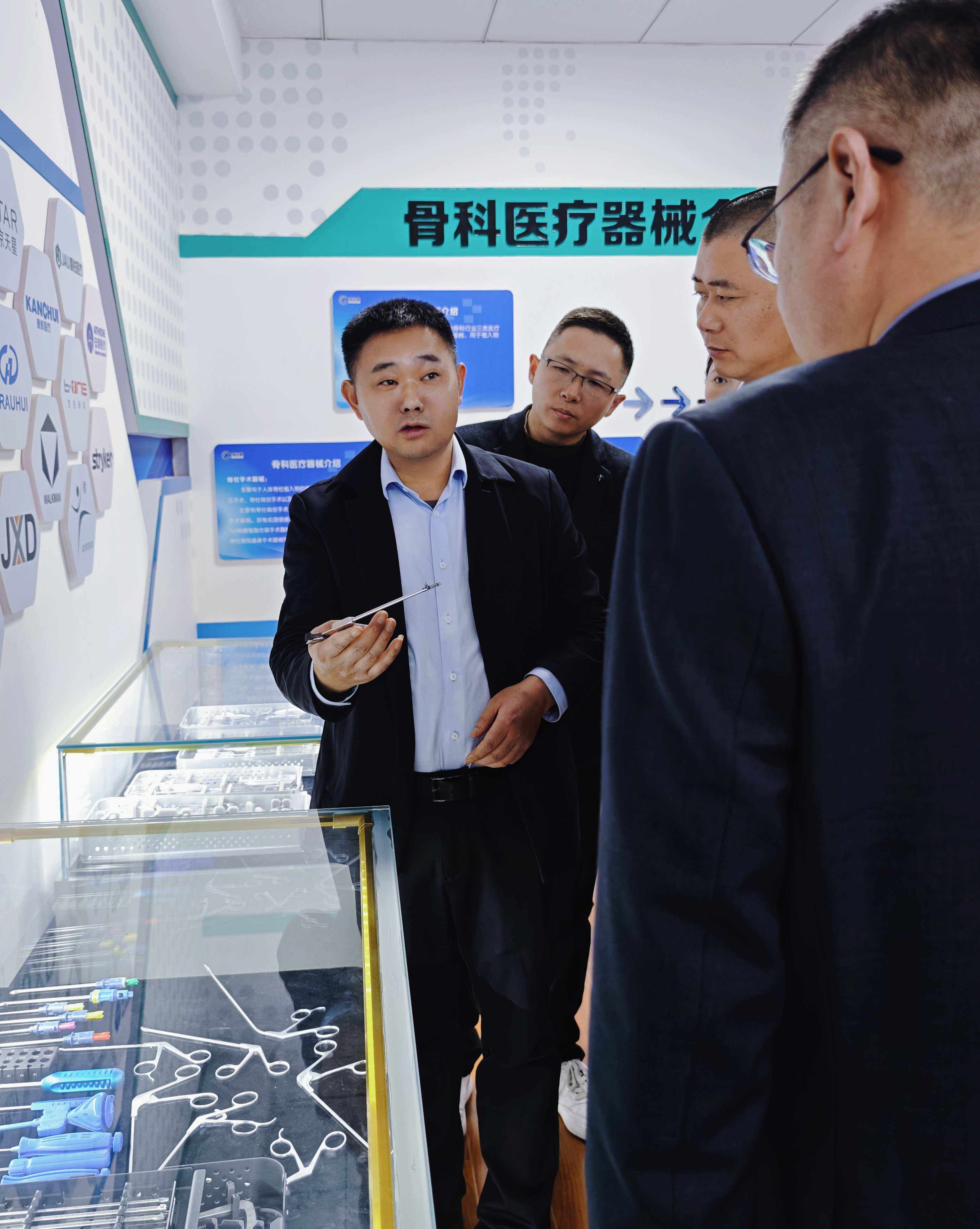

After the workshop tour, guests were guided to the corporate exhibition center, where a complete portfolio of medical components and engineering solutions was displayed. The center highlights a broad range of products including arthroscopy instruments, minimally invasive surgical tools, orthopedic implants, trauma fixation accessories, and a growing portfolio of components supporting surgical robotic systems.

General Manager Hong emphasized the company’s strategic development focus in sports medicine instruments and robot-assisted surgical device components. These two areas represent high-growth sectors in global medical technology, where precision, reliability, and design flexibility are critical. By integrating multi-axis machining, micro-fabrication processes, and advanced surface treatment technologies, the company continues to expand its capabilities to meet the rapidly evolving needs of international medical device partners.

The procurement delegation expressed high appreciation for the company’s technical strength, R&D capabilities, and equipment scale. Several guests noted that the production environment, process standardization, and quality control systems fully meet the expectations of global medical device manufacturing. They also highlighted the company’s ability to provide customized solutions based on customer drawings, performance requirements, and regulatory standards.

During the discussion session, both parties exchanged insights on future industrial trends. Topics included next-generation minimally invasive surgery instruments, precision machining challenges in robotic surgery components, potential joint development projects, and long-term supply chain cooperation models. The delegation affirmed their keen interest in deepening collaboration and indicated that the company’s manufacturing platform aligns closely with their procurement goals.

By the end of the meeting, both sides reached a strong consensus on establishing future cooperative frameworks. The delegation expressed confidence in the company’s comprehensive strength—from equipment investment and engineering capability to quality management and delivery reliability. They also recognized the company’s active role in advancing innovative medical manufacturing and promoting international cooperation.

This visit not only strengthened communication between the two parties but also laid a solid foundation for future strategic cooperation. As we continue to expand global partnerships, the company remains committed to delivering high-precision medical components, high-performance processing solutions, and internationally trusted quality to clients worldwide. The company will continue to uphold its mission of enabling innovation in medical technology through advanced manufacturing, engineering excellence, and reliable global service.

Hot News

Hot News2026-02-10

2025-12-18

2025-12-04

2025-11-25

2025-11-21

2025-11-20