When a patient with osteoarthritis regains steady mobility after receiving an artificial hip joint, it stands as a testament to countless precision manufacturing technologies. In the field of orthopedic medical devices, mill-turn machining centers, with their unique advantages, have emerged as a pivotal force in enhancing product quality and driving technological innovation.

Unique Challenges in Orthopedic Device Manufacturing

Orthopedic medical devices directly impact patients' health and quality of life, imposing stringent manufacturing requirements. Products such as artificial joints and spinal implants must not only achieve precise alignment with human bones but also possess excellent biocompatibility and mechanical properties.

Commonly used materials like titanium alloys and cobalt-chromium-molybdenum alloys meet biocompatibility needs but pose significant machining challenges. These materials, characterized by high strength and toughness, often lead to issues such as excessive cutting forces and poor heat dissipation during processing, placing severe demands on machine tool performance. Additionally, orthopedic devices typically feature complex curved surfaces and intricate structures—such as the spherical surfaces of artificial joints and the threads of spinal screws—requiring machining precision controlled at the micrometer level.

Traditional processing methods involve multiple clamping steps, which are not only inefficient but also prone to cumulative errors, failing to meet the high-precision requirements of orthopedic devices. The advent of mill-turn machining centers has provided an effective solution to these challenges.

Distinct Advantages of Mill-Turn Machining Centers

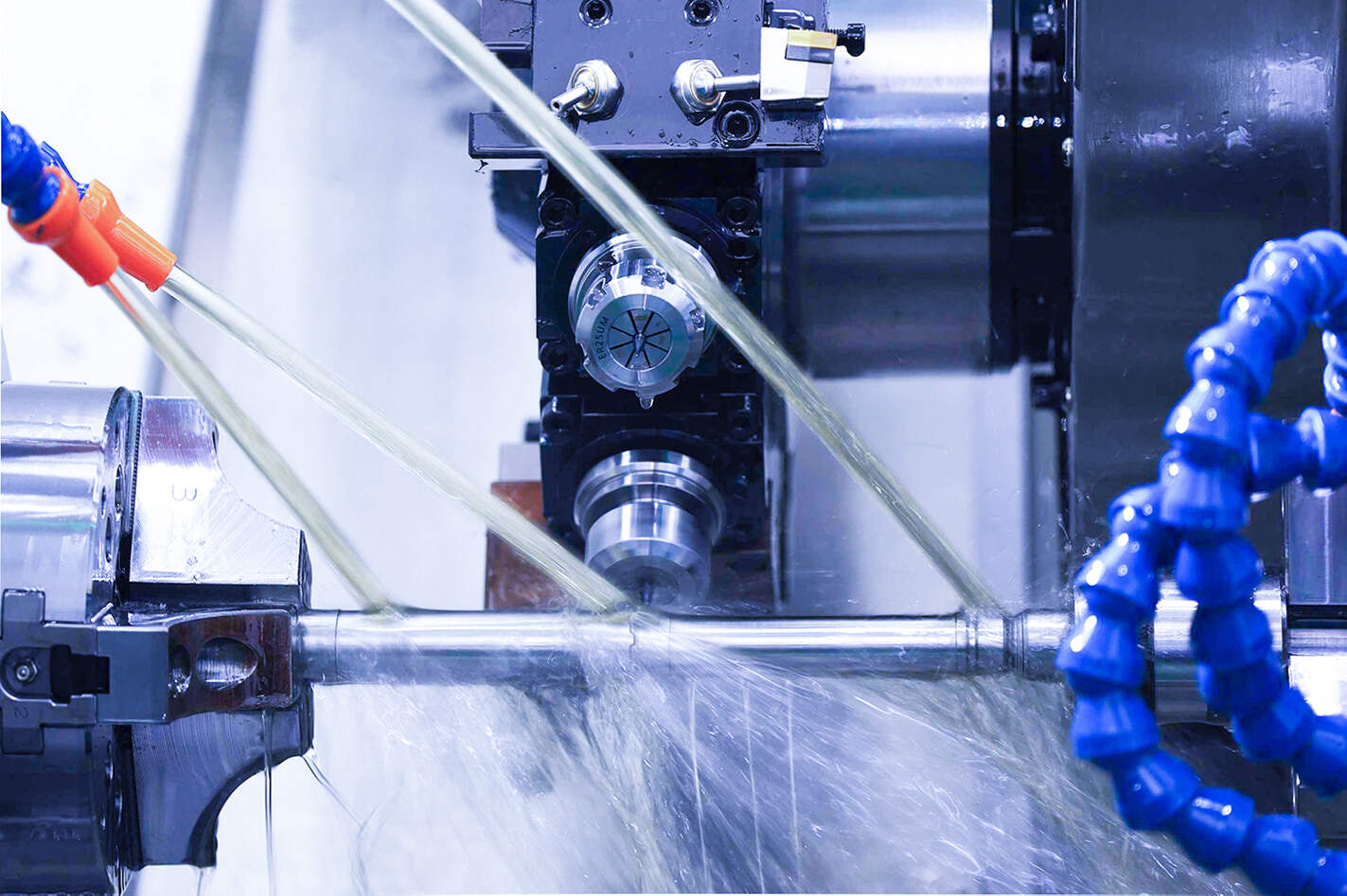

Mill-turn machining centers integrate multiple processing technologies—including turning, milling, and drilling—enabling most or all of a part's processing to be completed in a single clamping. This fundamentally reduces errors caused by multiple clampings. Their multi-axis linkage capability allows for precise machining of complex curved surfaces, making the intricate structures of orthopedic devices no longer manufacturing obstacles.

Take artificial knee joints as an example: the femoral condyle features a complex curved surface that must perfectly fit human bones. Through coordinated multi-axis movement, mill-turn machining centers can complete curved surface processing in one operation, achieving a machining accuracy of ±0.005mm and a surface roughness of Ra 0.8μm or lower—greatly reducing the risk of post-operative wear.

In terms of material processing, mill-turn machining centers are equipped with advanced numerical control systems that automatically adjust cutting parameters (such as cutting speed and feed rate) based on the properties of different materials. This effectively addresses the machining challenges of difficult-to-process materials like titanium alloys. Meanwhile, the machine's high-rigidity structure and stable drive system ensure processing stability, minimizing the impact of vibration on machining precision.

Driving Transformation in Orthopedic Healthcare

The application of mill-turn machining centers has not only improved the manufacturing quality and efficiency of orthopedic medical devices but also advanced the development of personalized medicine. With the integration of 3D printing technology and mill-turn machining, doctors can customize orthopedic implants based on patients' CT scan data.

First, 3D printing is used to produce blanks for personalized implants, which are then precision-machined using mill-turn centers. This approach ensures both perfect fit between the implant and the patient's bones and compliance with required mechanical properties. This personalized manufacturing method has been applied in fields such as pelvic reconstruction and scoliosis correction, significantly improving surgical success rates and patients' post-operative quality of life.

Hot News

Hot News