Selecting the right orthopedic trauma instruments factory represents a critical decision that can significantly impact surgical outcomes, cost efficiency, and long-term business success. Healthcare institutions, distributors, and medical device companies must carefully evaluate potential manufacturing partners to ensure quality, compliance, and reliability. The global orthopedic trauma market continues expanding, driven by aging populations and increased activity-related injuries, making the selection of a competent orthopedic trauma instruments factory more crucial than ever. Understanding the key factors in partnership evaluation helps organizations make informed decisions that benefit both their operational goals and patient care standards.

Essential Qualifications for Orthopedic Manufacturing Partners

Regulatory Compliance and Certifications

A reliable orthopedic trauma instruments factory must maintain comprehensive regulatory certifications that demonstrate adherence to international quality standards. ISO 13485 certification remains the gold standard for medical device manufacturing, ensuring systematic quality management throughout the production process. FDA registration and CE marking provide additional validation for factories serving global markets, while country-specific approvals enable market access in targeted regions. These certifications require ongoing audits and compliance monitoring, indicating a manufacturer's commitment to sustained quality excellence.

Beyond basic certifications, leading orthopedic trauma instruments factory operations implement advanced quality systems that exceed minimum regulatory requirements. Good Manufacturing Practice compliance ensures consistent production processes, while risk management systems identify and mitigate potential quality issues before they impact finished products. Documentation systems must provide complete traceability from raw materials through final inspection, enabling rapid response to any quality concerns or regulatory inquiries.

Manufacturing Capabilities and Technology

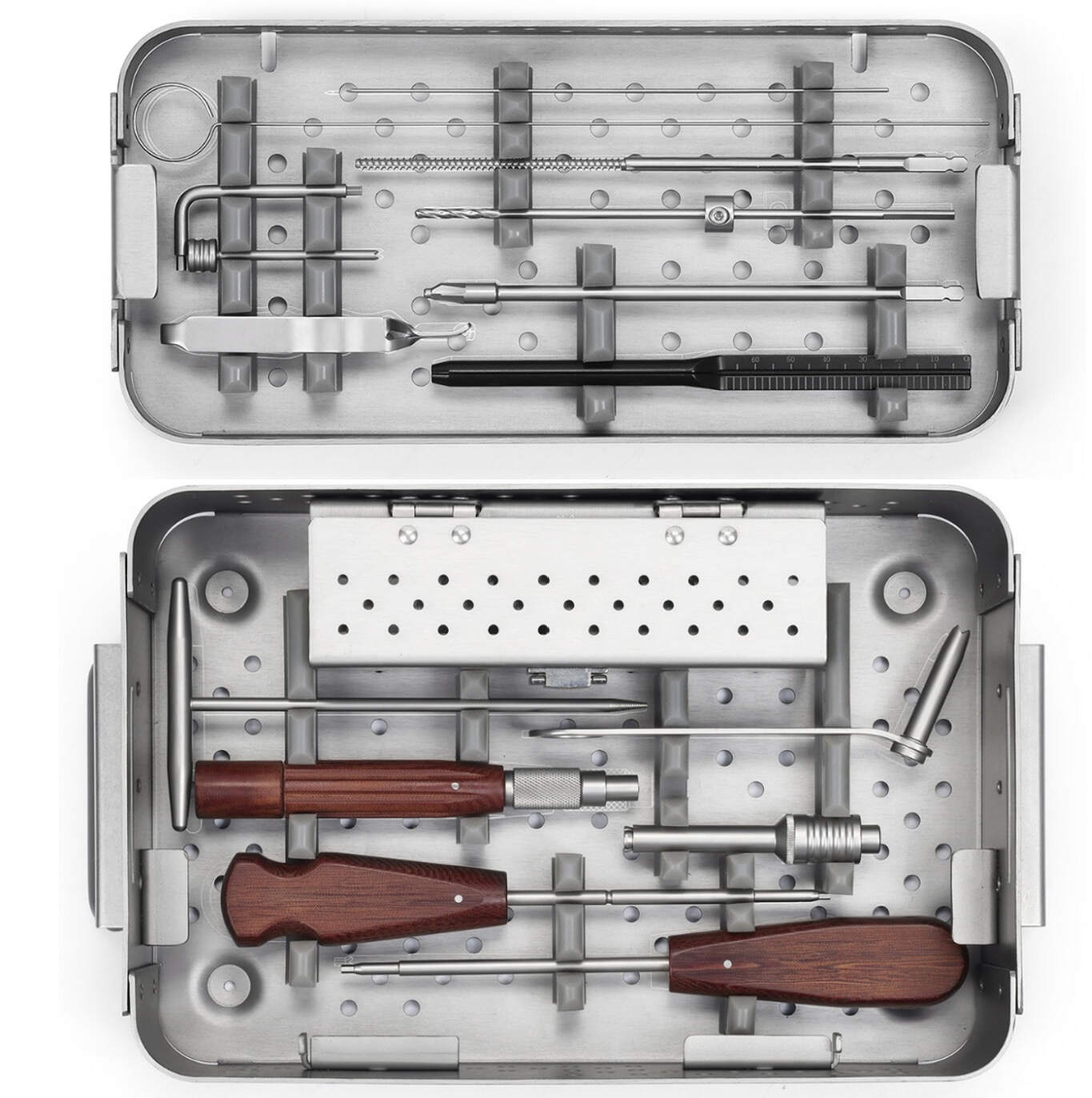

Modern orthopedic trauma instruments require precision manufacturing capabilities that can achieve tight tolerances and complex geometries consistently. CNC machining centers, EDM equipment, and advanced grinding systems enable the production of high-quality instruments that meet demanding surgical requirements. Investment in state-of-the-art manufacturing technology demonstrates a factory's commitment to quality and capability expansion, while also indicating financial stability and growth orientation.

Surface finishing capabilities play a crucial role in instrument performance, particularly for trauma applications where smooth surfaces reduce tissue trauma and improve cleaning efficiency. Electropolishing, passivation, and specialized coating technologies enhance instrument durability and biocompatibility, while laser marking provides permanent identification that withstands repeated sterilization cycles. A capable orthopedic trauma instruments factory should demonstrate expertise across multiple finishing techniques to accommodate diverse product requirements.

Evaluating Production Capacity and Scalability

Current Manufacturing Volume Assessment

Understanding a potential partner's current production capacity helps determine whether they can accommodate your volume requirements without compromising quality or delivery schedules. Established orthopedic trauma instruments factory operations typically maintain detailed capacity planning systems that track machine utilization, labor allocation, and material flow throughout their facilities. This information enables accurate delivery commitments and helps identify potential bottlenecks before they impact production schedules.

Production flexibility represents another critical factor, as trauma instrument demand can fluctuate significantly based on seasonal patterns, emergency situations, or market dynamics. Factories with diverse product portfolios and flexible manufacturing systems can better accommodate volume variations while maintaining cost efficiency. Multiple production lines and cross-trained personnel provide additional resilience against disruptions, ensuring consistent supply availability.

Expansion and Growth Capabilities

Long-term partnerships require manufacturers who can grow alongside your business needs, making scalability assessment essential during the selection process. An orthopedic trauma instruments factory with documented expansion plans and available facility space demonstrates forward-thinking management and growth capability. Investment in additional equipment, facility improvements, and workforce development indicates commitment to supporting customer growth requirements.

Geographic expansion capabilities enable manufacturers to serve global markets more effectively while potentially reducing logistics costs and delivery times. Multiple manufacturing locations provide supply chain resilience and may offer cost advantages through regional labor markets or material sourcing opportunities. However, multi-site operations require sophisticated quality management systems to ensure consistency across all manufacturing locations.

Quality Assurance and Testing Protocols

Incoming Material Inspection Systems

Comprehensive quality assurance begins with rigorous incoming material inspection protocols that verify raw material specifications before production begins. Leading orthopedic trauma instruments factory operations maintain approved supplier lists with documented qualification processes, ensuring consistent material quality from trusted sources. Material certificates, chemical analysis, and mechanical testing provide verification that incoming materials meet specified requirements for strength, corrosion resistance, and biocompatibility.

Advanced material testing capabilities including spectrographic analysis, hardness testing, and microstructure evaluation enable thorough material characterization beyond basic supplier certifications. These capabilities become particularly important when working with specialty alloys or developing new products with unique material requirements. Documented material traceability systems ensure complete accountability from supplier delivery through finished product shipment.

In-Process and Final Inspection Procedures

Effective in-process inspection procedures prevent defective products from advancing through production stages, reducing waste and ensuring consistent quality output. Statistical process control systems monitor critical dimensions and characteristics throughout manufacturing, enabling real-time adjustments to maintain specifications. Coordinate measuring machines, optical comparators, and specialized gauging systems provide accurate measurement capabilities for complex instrument geometries.

Final inspection protocols must verify all critical characteristics including dimensions, surface finish, functionality, and cleanliness before product release. Comprehensive inspection documentation provides objective evidence of conformance while enabling continuous improvement through trend analysis. An orthopedic trauma instruments factory with robust inspection systems demonstrates commitment to quality excellence and customer satisfaction.

Supply Chain Management and Logistics

Raw Material Sourcing Strategies

Effective supply chain management ensures consistent material availability while maintaining cost competitiveness and quality standards. Successful orthopedic trauma instruments factory operations typically maintain strategic supplier relationships with multiple sources for critical materials, reducing dependency risks and enabling competitive pricing. Supplier development programs help maintain quality standards while fostering innovation and continuous improvement throughout the supply chain.

Material forecasting and inventory management systems enable proactive purchasing decisions that prevent production delays while minimizing carrying costs. Advanced planning systems consider lead times, minimum order quantities, and seasonal demand patterns to optimize inventory levels. Safety stock strategies protect against supply disruptions while balancing inventory costs against service level requirements.

Distribution and Delivery Capabilities

Efficient distribution systems ensure timely product delivery while maintaining product integrity throughout the logistics chain. Experienced orthopedic trauma instruments factory partners maintain established relationships with reliable freight carriers and understand international shipping requirements including customs documentation and regulatory compliance. Packaging systems protect products during transit while minimizing shipping costs through optimized dimensions and weight.

Order management systems provide real-time visibility into production schedules, inventory levels, and shipment status, enabling proactive communication and issue resolution. Electronic data interchange capabilities facilitate seamless information exchange between partners, reducing administrative overhead and improving accuracy. Emergency expediting capabilities ensure critical orders can be prioritized when necessary to support urgent clinical needs.

Cost Structure and Pricing Models

Manufacturing Cost Components

Understanding the cost structure of an orthopedic trauma instruments factory helps evaluate pricing competitiveness while ensuring sustainable partnerships. Material costs typically represent the largest component, influenced by alloy selection, market conditions, and procurement efficiency. Labor costs vary significantly by geographic region and skill requirements, while overhead costs reflect facility expenses, equipment depreciation, and administrative functions.

Value engineering capabilities enable cost optimization without compromising quality or functionality, providing ongoing benefits throughout the partnership. Design for manufacturability expertise helps identify cost reduction opportunities during product development while maintaining performance requirements. Continuous improvement initiatives demonstrate commitment to efficiency gains that benefit both manufacturing partners and end customers.

Pricing Transparency and Flexibility

Transparent pricing models provide clear understanding of cost drivers and enable informed decision-making throughout the partnership. Volume-based pricing structures reward larger commitments while providing predictable cost structures for business planning. Contract manufacturing arrangements may offer different pricing models compared to product purchasing agreements, requiring careful evaluation of total cost implications.

Price adjustment mechanisms should account for material cost fluctuations, labor rate changes, and other market factors that impact manufacturing costs. Regular pricing reviews ensure continued competitiveness while maintaining fairness for both parties. Long-term agreements may provide pricing stability in exchange for volume commitments, benefiting both partners through reduced uncertainty.

Technology Integration and Innovation Support

Design and Engineering Capabilities

Advanced design and engineering capabilities enable orthopedic trauma instruments factory partners to support product development initiatives and customization requirements. Computer-aided design systems, finite element analysis, and rapid prototyping capabilities accelerate development cycles while ensuring optimal product performance. Engineering expertise in biomechanics, materials science, and manufacturing processes provides valuable input throughout the development process.

Collaborative development approaches leverage manufacturing expertise during design phases, identifying opportunities to improve functionality, reduce costs, or enhance manufacturability. Design validation testing capabilities enable comprehensive performance evaluation before full production commitment. Intellectual property management systems protect proprietary designs while enabling necessary manufacturing documentation and process development.

Continuous Improvement and Innovation Programs

Leading orthopedic trauma instruments factory operations maintain formal continuous improvement programs that drive efficiency gains and quality enhancements. Lean manufacturing principles, Six Sigma methodologies, and employee suggestion programs create cultures focused on ongoing optimization. Innovation investments in new technologies, materials, and processes demonstrate commitment to staying current with industry developments.

Research and development partnerships with universities, medical institutions, and technology companies provide access to cutting-edge developments in orthopedic trauma treatment. Clinical feedback integration systems capture user experiences and translate them into product improvements. These innovation capabilities position manufacturing partners as valuable contributors to long-term product success and market competitiveness.

FAQ

What certifications should an orthopedic trauma instruments factory maintain

Essential certifications include ISO 13485 for medical device quality management, FDA registration for US market access, and CE marking for European compliance. Additional certifications may include ISO 14001 for environmental management and OHSAS 18001 for occupational health and safety. Country-specific approvals enable market access in targeted regions, while industry-specific certifications demonstrate specialized expertise in orthopedic trauma applications.

How can I evaluate the production capacity of a potential manufacturing partner

Request detailed information about current production volumes, equipment capacity, and workforce capabilities. Review their facility layout, machine specifications, and production planning systems to understand throughput capabilities. Ask for references from existing customers with similar volume requirements and request capacity utilization data to ensure they can accommodate your needs without overcommitting their resources.

What quality assurance measures are most important in trauma instrument manufacturing

Critical quality measures include comprehensive material testing, in-process dimensional verification, surface finish inspection, and functional testing. Traceability systems should track products from raw materials through final shipment, while statistical process control monitors critical characteristics throughout production. Final inspection protocols must verify all specifications before product release, supported by documented quality management systems.

How should I assess the long-term viability of an orthopedic trauma instruments factory partnership

Evaluate the manufacturer's financial stability, growth plans, and investment in technology and capacity expansion. Review their customer base diversity to understand dependency risks and assess their commitment to the orthopedic market. Consider their innovation capabilities, continuous improvement programs, and ability to adapt to changing regulatory requirements or market conditions that may impact long-term partnership success.

Table of Contents

- Essential Qualifications for Orthopedic Manufacturing Partners

- Evaluating Production Capacity and Scalability

- Quality Assurance and Testing Protocols

- Supply Chain Management and Logistics

- Cost Structure and Pricing Models

- Technology Integration and Innovation Support

-

FAQ

- What certifications should an orthopedic trauma instruments factory maintain

- How can I evaluate the production capacity of a potential manufacturing partner

- What quality assurance measures are most important in trauma instrument manufacturing

- How should I assess the long-term viability of an orthopedic trauma instruments factory partnership