The medical device industry faces unprecedented cost pressures as healthcare systems worldwide demand both quality and affordability in surgical solutions. Orthopedic surgery instruments manufacturing represents a critical segment within this landscape, where precision engineering meets stringent regulatory requirements while maintaining competitive pricing structures. Understanding the comprehensive cost factors involved in producing these specialized medical tools enables healthcare institutions and manufacturers to make informed decisions about procurement strategies and operational efficiency.

Manufacturing costs in the orthopedic sector extend far beyond basic material expenses, encompassing sophisticated quality control systems, regulatory compliance measures, and advanced manufacturing technologies. Modern orthopedic surgery instruments manufacturing requires substantial investments in research and development, specialized tooling, and highly skilled personnel capable of meeting the exacting standards demanded by surgical applications. These factors collectively contribute to the overall cost structure that ultimately influences market pricing and accessibility of essential surgical instruments.

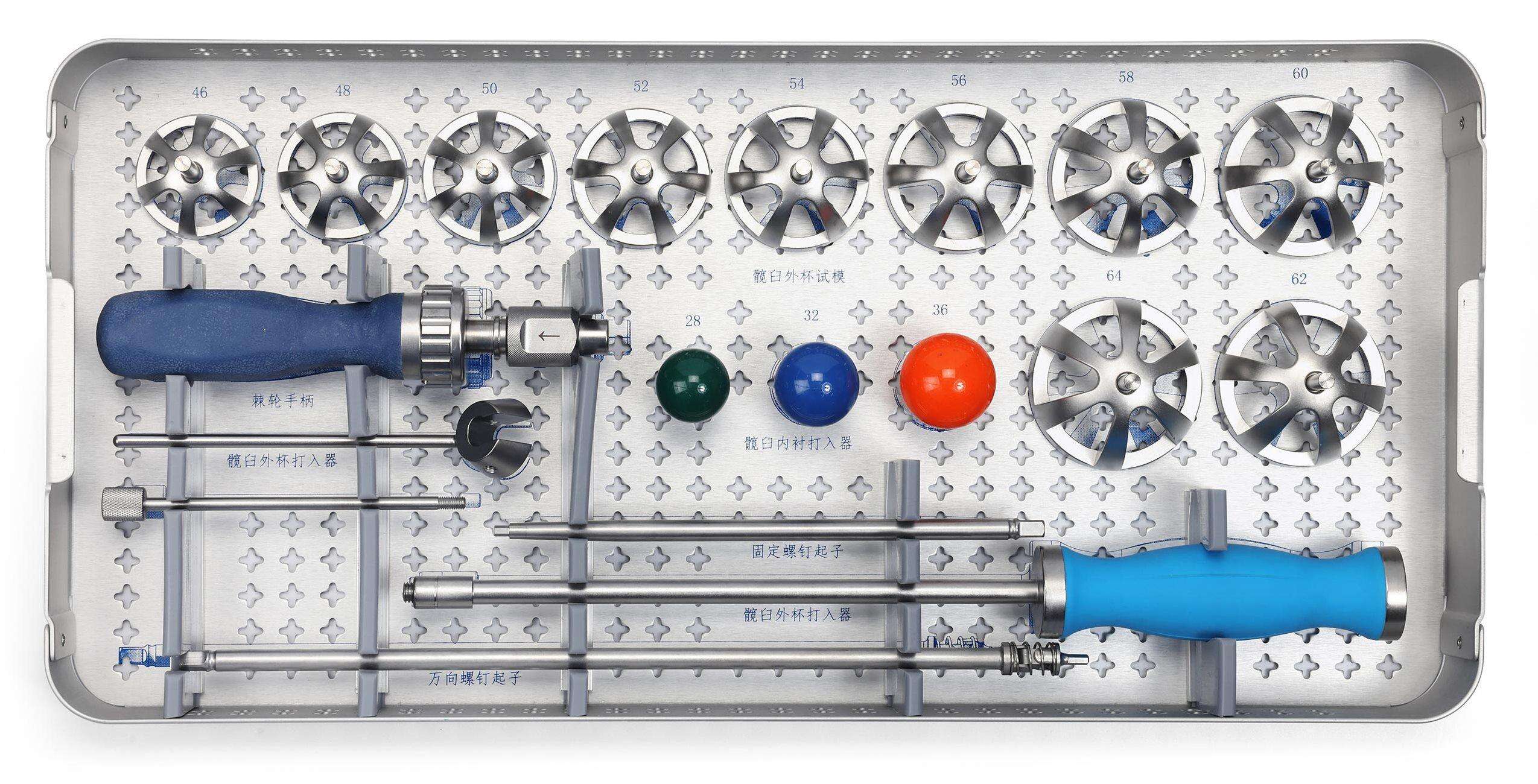

Raw Material Costs and Quality Standards

Premium Grade Steel Selection

The foundation of orthopedic surgery instruments manufacturing lies in the selection of premium-grade stainless steel alloys, typically 316L or 17-4 PH stainless steel, which command significantly higher prices than standard industrial materials. These specialized alloys provide essential characteristics including corrosion resistance, biocompatibility, and the ability to maintain sharp cutting edges through multiple sterilization cycles. Material costs can represent up to thirty percent of total manufacturing expenses, making steel selection a critical factor in overall cost analysis.

Procurement strategies for raw materials often involve long-term contracts with certified suppliers to ensure consistent quality and pricing stability. The orthopedic surgery instruments manufacturing sector requires materials that meet specific ASTM and ISO standards, with documented traceability throughout the supply chain. Price volatility in specialty steel markets can significantly impact manufacturing costs, necessitating careful inventory management and strategic sourcing partnerships to maintain competitive positioning while ensuring material quality remains uncompromised.

Surface Treatment and Finishing Requirements

Surface treatments such as passivation, electropolishing, and specialized coatings add considerable expense to the manufacturing process while providing essential performance characteristics. These treatments ensure optimal biocompatibility, reduce bacterial adhesion, and enhance the longevity of surgical instruments. The cost of these finishing processes can range from fifteen to twenty-five percent of total production expenses, depending on the complexity of the instrument design and required performance specifications.

Advanced surface treatments like titanium nitride coating or diamond-like carbon applications require specialized equipment and expertise, further increasing production costs. However, these premium finishes often justify their expense through improved surgical performance and extended instrument lifespan. Manufacturers must carefully balance the cost of enhanced surface treatments against market demand and competitive pricing pressures while maintaining the quality standards expected in orthopedic surgery instruments manufacturing applications.

Manufacturing Technology and Equipment Investments

Precision Machining Infrastructure

Modern orthopedic surgery instruments manufacturing relies heavily on computer numerical control machining centers, wire electrical discharge machining systems, and advanced grinding equipment capable of achieving tolerances measured in microns. Initial capital investments in this sophisticated machinery can exceed several million dollars for a comprehensive manufacturing facility. The depreciation and maintenance costs associated with precision equipment represent a substantial ongoing expense that must be factored into product pricing strategies.

Technological advancement in manufacturing equipment offers opportunities for improved efficiency and reduced per-unit costs over time. However, the rapid pace of innovation in machining technology requires continuous investment in equipment upgrades and operator training to remain competitive. The orthopedic surgery instruments manufacturing industry must balance the benefits of cutting-edge technology against the financial burden of frequent equipment updates, particularly for smaller manufacturers operating with limited capital resources.

Quality Control and Testing Systems

Comprehensive quality control systems represent a significant cost component in orthopedic surgery instruments manufacturing, with sophisticated coordinate measuring machines, hardness testers, and material analysis equipment requiring substantial investment. Each instrument typically undergoes multiple inspection stages, from raw material verification through final product validation, with testing costs potentially representing ten to fifteen percent of total manufacturing expenses depending on the complexity of quality requirements.

Implementation of statistical process control systems and automated inspection technologies can reduce long-term quality control costs while improving consistency and reducing defect rates. However, the initial investment in advanced quality systems requires careful financial planning and often represents a barrier to entry for smaller manufacturers. The cost of quality failures in surgical instruments can be catastrophic, making robust quality control systems a necessary expense rather than an optional enhancement in orthopedic surgery instruments manufacturing operations.

Regulatory Compliance and Certification Expenses

FDA and International Regulatory Requirements

Regulatory compliance costs in orthopedic surgery instruments manufacturing encompass FDA registration fees, quality management system certification, and ongoing regulatory maintenance activities that can consume significant financial resources. Initial FDA 510(k) submissions typically cost between fifty thousand and two hundred thousand dollars, depending on the complexity of the device and required clinical data. International regulatory requirements add additional layers of expense, with CE marking, Health Canada licensing, and other regional certifications each requiring separate documentation and fees.

Maintaining regulatory compliance requires dedicated personnel with specialized expertise in medical device regulations, quality assurance protocols, and documentation management. The annual cost of regulatory compliance can range from two to five percent of total revenue for established manufacturers, with higher percentages common for smaller companies or those introducing new product lines. Changes in regulatory requirements can trigger substantial additional expenses for design modifications, testing, and resubmission processes that must be absorbed within existing product pricing structures.

Quality Management System Implementation

ISO 13485 certification and FDA Quality System Regulation compliance require comprehensive documentation systems, regular internal audits, and third-party surveillance activities that generate ongoing operational expenses. Implementation of robust quality management systems typically requires six to eighteen months and can cost between one hundred thousand and five hundred thousand dollars, depending on the size and complexity of the manufacturing operation. These systems are essential for maintaining regulatory compliance and ensuring consistent product quality in orthopedic surgery instruments manufacturing.

The operational burden of maintaining quality management systems includes regular employee training, document control activities, and management review processes that consume significant personnel resources. While these activities do not directly contribute to production output, they are essential for regulatory compliance and risk management. Manufacturers must carefully allocate resources to quality management activities while maintaining operational efficiency and competitive cost structures in their orthopedic surgery instruments manufacturing operations.

Labor and Skilled Workforce Requirements

Specialized Manufacturing Personnel

Orthopedic surgery instruments manufacturing requires highly skilled machinists, quality control technicians, and engineering personnel capable of working with tight tolerances and complex geometries. Compensation for skilled manufacturing personnel typically exceeds standard industrial wages by twenty to forty percent, reflecting the specialized knowledge and experience required for medical device production. Training new employees in the specific requirements of surgical instrument manufacturing can require three to six months and represents a significant investment in human capital development.

Employee retention strategies become critical in managing labor costs, as the departure of experienced personnel can disrupt production schedules and require expensive retraining programs. Benefits packages for skilled manufacturing workers often include comprehensive health insurance, retirement contributions, and continuing education opportunities that add substantial costs beyond base wages. The competitive market for skilled manufacturing talent requires ongoing investment in employee development and workplace amenities to maintain a stable workforce capable of supporting consistent production quality.

Engineering and Design Capabilities

Product development in orthopedic surgery instruments manufacturing requires specialized engineering expertise in biomechanics, materials science, and surgical procedure optimization. Engineering personnel compensation typically represents fifteen to twenty-five percent of total labor costs, with senior engineers commanding salaries comparable to those in aerospace and other high-technology industries. The cost of maintaining in-house engineering capabilities must be balanced against the benefits of rapid product development and proprietary design protection.

Collaboration between engineering teams and surgical professionals requires additional resources for clinical consultation, prototype development, and iterative design refinement. These activities generate substantial costs before any revenue is realized from new product introductions. Successful orthopedic surgery instruments manufacturing companies typically invest three to eight percent of annual revenue in research and development activities, with the understanding that innovative products command premium pricing and stronger market positions over time.

Production Volume and Economies of Scale

Fixed Cost Distribution Strategies

Manufacturing overhead costs in orthopedic surgery instruments manufacturing include facility expenses, equipment depreciation, utilities, and administrative support that remain relatively constant regardless of production volume. Achieving sufficient production volume to distribute these fixed costs effectively across multiple units represents a critical success factor for maintaining competitive pricing. Low-volume specialty instruments may carry overhead allocations that significantly impact their market competitiveness compared to high-volume standard products.

Strategic planning for production volume optimization requires careful market analysis and demand forecasting to balance inventory investment against manufacturing efficiency. Orthopedic surgery instruments manufacturing often involves producing instruments in batches to optimize setup times and material utilization, with batch sizes influenced by demand patterns and inventory carrying costs. Manufacturers must carefully balance the benefits of larger production runs against the risks of obsolete inventory and changing market requirements.

Supply Chain Integration and Vendor Management

Effective supply chain management can significantly impact overall manufacturing costs through strategic vendor partnerships, volume purchasing agreements, and integrated logistics solutions. Orthopedic surgery instruments manufacturing typically involves multiple suppliers for raw materials, components, packaging, and specialized services, each requiring careful evaluation and ongoing performance monitoring. Consolidating suppliers where possible can reduce administrative costs and improve negotiating leverage for better pricing terms.

Long-term supplier relationships often provide opportunities for cost reduction through collaborative improvement initiatives, joint process optimization, and shared technology development. However, single-source dependencies can create supply chain risks that must be carefully managed through backup supplier qualification and strategic inventory management. The cost of supply chain disruptions in orthopedic surgery instruments manufacturing can be particularly severe due to the critical nature of surgical procedures and the difficulty of rapid supplier substitution for specialized components.

Market Competition and Pricing Strategies

Competitive Positioning Analysis

Market positioning in orthopedic surgery instruments manufacturing requires careful analysis of competitor pricing structures, product differentiation opportunities, and value proposition development. Premium pricing strategies may be sustainable for innovative products with demonstrated clinical advantages, while commodity instruments face intense price competition that demands exceptional manufacturing efficiency. Understanding the total cost of ownership from the customer perspective enables manufacturers to develop pricing strategies that reflect true value rather than simply manufacturing costs plus margin.

Competitive intelligence gathering and market research activities consume resources but provide essential information for strategic decision-making regarding product development priorities and pricing optimization. The orthopedic surgery instruments manufacturing market includes both large multinational corporations with substantial economies of scale and specialized niche manufacturers focusing on specific surgical procedures or geographic markets. Each competitive segment requires tailored approaches to cost management and pricing strategy development.

Value-Based Pricing Opportunities

Value-based pricing in orthopedic surgery instruments manufacturing considers factors beyond manufacturing costs, including clinical outcomes, surgical efficiency improvements, and total procedure costs. Instruments that enable faster surgical procedures, reduce complications, or improve patient outcomes may justify premium pricing despite higher manufacturing costs. Documenting and communicating value propositions requires investment in clinical studies, outcome measurements, and marketing activities that add to overall business costs but can support superior pricing strategies.

Healthcare institutions increasingly evaluate surgical instruments based on total cost of ownership rather than initial purchase price alone. This trend creates opportunities for manufacturers to differentiate their products through superior durability, reduced maintenance requirements, or enhanced performance characteristics that justify higher initial costs. Successful value-based pricing requires comprehensive understanding of customer operations and the ability to quantify the economic impact of product performance improvements in orthopedic surgery instruments manufacturing applications.

FAQ

What percentage of manufacturing costs comes from raw materials in orthopedic instrument production

Raw materials typically represent twenty-five to thirty-five percent of total manufacturing costs in orthopedic surgery instruments manufacturing, with premium stainless steel alloys commanding significantly higher prices than standard industrial materials. The exact percentage varies based on instrument complexity, required material specifications, and current market conditions for specialty steel products. Material costs can fluctuate substantially based on global supply chain conditions and commodity pricing trends.

How do regulatory compliance costs impact overall manufacturing expenses

Regulatory compliance costs typically consume two to five percent of annual revenue for established manufacturers, including FDA registration fees, quality system maintenance, and ongoing regulatory activities. Initial regulatory submissions for new products can cost between fifty thousand and two hundred thousand dollars, depending on device complexity and required clinical data. These costs are essential for market access but represent significant barriers to entry for smaller manufacturers in the orthopedic surgery instruments manufacturing sector.

What are the typical equipment investment requirements for starting orthopedic instrument manufacturing

Initial equipment investments for comprehensive orthopedic surgery instruments manufacturing facilities typically range from two to ten million dollars, depending on production capacity and automation levels. Essential equipment includes precision CNC machining centers, heat treatment systems, quality control instrumentation, and specialized finishing equipment. Smaller facilities focusing on specific instrument types may require lower initial investments but face limitations in product diversification and economies of scale.

How does production volume affect per-unit manufacturing costs

Production volume significantly impacts per-unit costs through fixed cost distribution, with low-volume specialty instruments potentially carrying overhead allocations that are three to five times higher than high-volume products. Achieving optimal production volumes requires careful market analysis and strategic planning to balance inventory investment against manufacturing efficiency. Orthopedic surgery instruments manufacturing benefits substantially from economies of scale, particularly for standardized instruments with consistent demand patterns across multiple healthcare institutions.

Table of Contents

- Raw Material Costs and Quality Standards

- Manufacturing Technology and Equipment Investments

- Regulatory Compliance and Certification Expenses

- Labor and Skilled Workforce Requirements

- Production Volume and Economies of Scale

- Market Competition and Pricing Strategies

-

FAQ

- What percentage of manufacturing costs comes from raw materials in orthopedic instrument production

- How do regulatory compliance costs impact overall manufacturing expenses

- What are the typical equipment investment requirements for starting orthopedic instrument manufacturing

- How does production volume affect per-unit manufacturing costs