Medical device companies face a critical decision when selecting partners for orthopedic implant production. The choice between cost savings and quality assurance becomes particularly complex when working with an orthopedic oem manufacturer. This fundamental business challenge requires careful evaluation of multiple factors, from regulatory compliance to long-term market positioning. Understanding the true cost implications while maintaining exceptional quality standards determines success in today's competitive orthopedic market. Healthcare providers and patients ultimately depend on these crucial manufacturing decisions, making the selection process both strategic and ethical.

Understanding Orthopedic OEM Manufacturing Economics

Initial Investment Considerations

The upfront costs associated with orthopedic manufacturing partnerships extend far beyond simple per-unit pricing. Tooling development, regulatory documentation, and quality system validation represent substantial initial investments. Companies must evaluate whether an orthopedic oem manufacturer possesses the necessary infrastructure to support complex implant production without compromising standards. These foundational expenses often determine the long-term viability of manufacturing relationships. Smart organizations recognize that lower initial quotes may conceal hidden costs in regulatory compliance, quality control, and post-market surveillance activities.

Manufacturing setup costs vary significantly depending on implant complexity and regulatory requirements. Simple orthopedic devices may require minimal tooling investment, while complex joint replacement systems demand sophisticated manufacturing capabilities. The chosen manufacturing partner must demonstrate proven experience with similar product categories to minimize development risks. Cost projections should include comprehensive validation testing, regulatory submission support, and ongoing quality assurance programs. Financial planning must account for potential delays, design modifications, and regulatory feedback that commonly occur during product development phases.

Long-Term Financial Implications

Sustainable manufacturing partnerships require transparent cost structures that accommodate market fluctuations and regulatory changes. An experienced orthopedic oem manufacturer understands how to structure pricing models that protect both parties from unexpected cost increases. Volume commitments, material sourcing strategies, and capacity planning directly impact long-term manufacturing costs. Companies should negotiate pricing frameworks that incentivize quality improvements while maintaining competitive market positioning. Regular cost reviews and performance benchmarking ensure manufacturing partnerships remain economically viable throughout product lifecycles.

Hidden costs often emerge in manufacturing relationships that prioritize initial savings over comprehensive planning. Quality failures, regulatory delays, and supply chain disruptions can quickly eliminate perceived cost advantages. Wise organizations invest in manufacturing partners who demonstrate proactive risk management and transparent communication practices. The true cost of orthopedic manufacturing includes warranty exposure, recall potential, and reputational risks that extend far beyond production expenses. Building relationships with manufacturers who understand these broader implications protects long-term business interests and patient safety.

Quality Standards and Regulatory Compliance

FDA and International Regulatory Requirements

Orthopedic device manufacturing operates under some of the most stringent regulatory frameworks in the medical device industry. ISO 13485 certification, FDA Quality System Regulation compliance, and MDR conformity represent baseline requirements for legitimate manufacturing partners. An orthopedic oem manufacturer must demonstrate comprehensive understanding of these regulatory landscapes to ensure market access. Documentation requirements, design controls, and risk management processes demand sophisticated quality management systems. Manufacturing partners without proper regulatory credentials expose their clients to significant market access risks and potential legal liabilities.

International market access requires manufacturers to navigate multiple regulatory jurisdictions simultaneously. European MDR, Health Canada requirements, and emerging market regulations create complex compliance matrices that experienced manufacturers understand intimately. The chosen manufacturing partner should maintain current registrations and demonstrate successful product approvals across target markets. Regulatory expertise becomes particularly valuable when addressing post-market surveillance requirements, adverse event reporting, and quality system inspections. Companies benefit from manufacturing partners who proactively manage regulatory relationships and maintain current industry certifications.

Manufacturing Process Validation

Process validation represents a critical quality checkpoint that separates professional manufacturers from cost-focused alternatives. Comprehensive validation protocols ensure consistent product quality, regulatory compliance, and patient safety throughout production runs. Experienced orthopedic manufacturers understand how to develop robust validation strategies that satisfy regulatory requirements while maintaining production efficiency. Statistical process control, capability studies, and ongoing monitoring programs demonstrate manufacturing maturity and quality commitment. These validation investments protect against quality failures that could result in costly recalls or regulatory actions.

Quality system maturity becomes evident through detailed process documentation, employee training programs, and continuous improvement initiatives. Manufacturing partners should demonstrate established corrective and preventive action systems, supplier qualification programs, and comprehensive quality metrics. Regular quality audits, customer feedback integration, and proactive risk assessment activities indicate sophisticated quality management capabilities. The investment in comprehensive quality systems pays dividends through reduced quality incidents, improved regulatory compliance, and enhanced customer satisfaction. Manufacturing partners who view quality as a competitive advantage rather than a cost center typically deliver superior long-term value.

Material Selection and Sourcing Strategies

Biomaterial Quality Standards

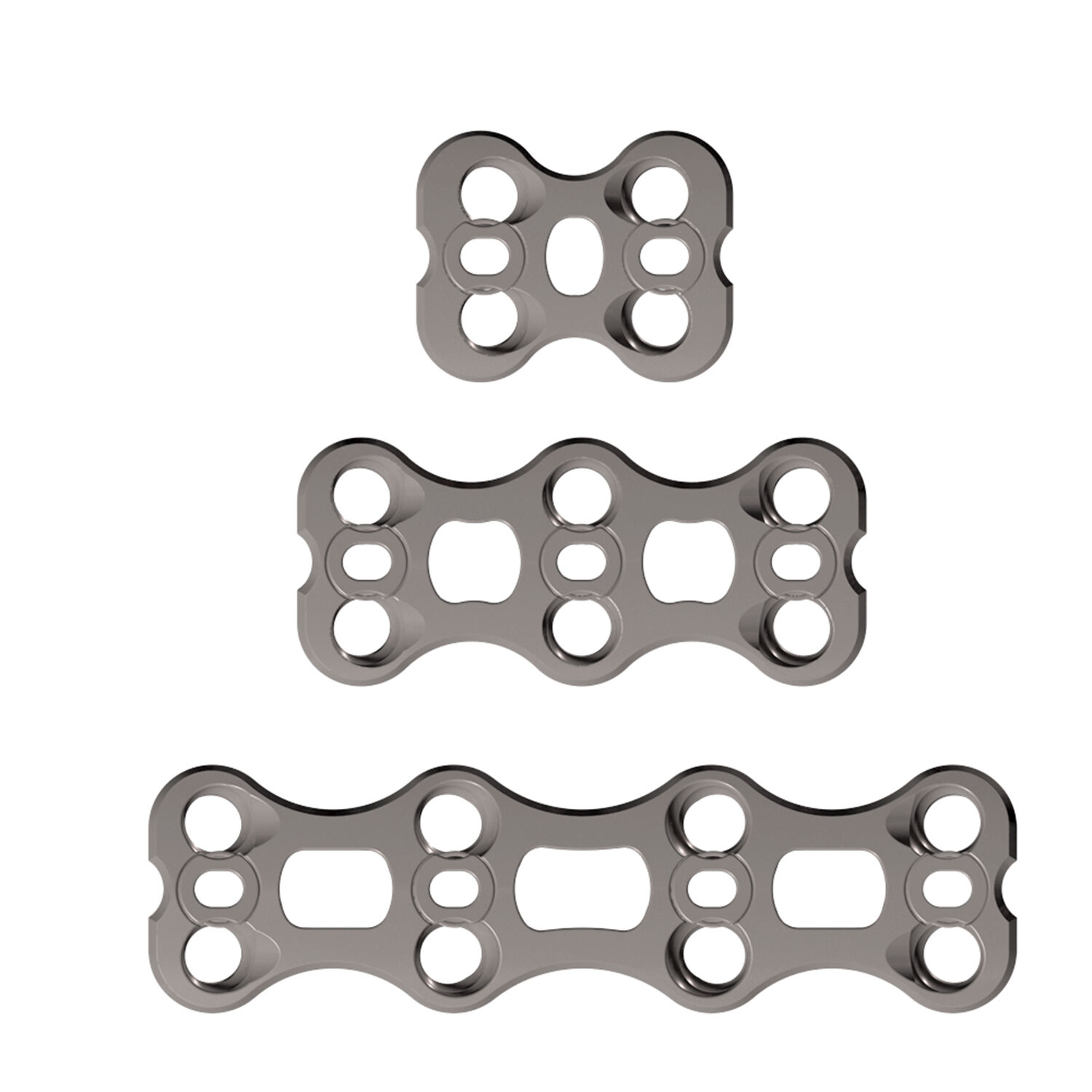

Orthopedic implant materials must meet exacting biocompatibility, mechanical property, and traceability requirements that significantly impact manufacturing costs. Titanium alloys, cobalt chromium, and ultra-high molecular weight polyethylene represent premium materials with established clinical track records. An experienced orthopedic oem manufacturer maintains relationships with qualified material suppliers who understand medical device requirements and maintain appropriate certifications. Material sourcing strategies should prioritize consistency, traceability, and regulatory compliance over simple cost reduction. The material selection process directly influences implant performance, patient outcomes, and long-term product liability exposure.

Material certification and traceability requirements add complexity and cost to orthopedic manufacturing processes. Each material lot must include comprehensive documentation covering chemical composition, mechanical properties, and biocompatibility testing results. Manufacturing partners should demonstrate established material qualification procedures and ongoing supplier management programs. Certificate of compliance documentation, material test reports, and traceability matrices ensure regulatory compliance and support post-market surveillance activities. These material management investments protect against quality issues while enabling efficient regulatory submissions and customer audits.

Supply Chain Risk Management

Global supply chain disruptions have highlighted the importance of diversified sourcing strategies and risk mitigation planning. Responsible orthopedic manufacturers maintain multiple qualified suppliers for critical materials and implement comprehensive risk assessment procedures. Supply chain visibility, alternative sourcing options, and inventory management strategies protect against production delays and cost volatility. Manufacturing partners should demonstrate proactive supply chain management and transparent communication regarding potential disruptions. The investment in supply chain resilience provides significant value during market uncertainties and material shortage periods.

Supplier qualification and ongoing management programs require significant investment but provide essential risk mitigation benefits. Quality audits, performance monitoring, and continuous improvement initiatives ensure supplier capabilities meet evolving requirements. Manufacturing partners should maintain current supplier certifications and demonstrate established supplier development programs. These supplier management investments reduce quality risks, improve delivery performance, and support continuous cost optimization initiatives. Strong supplier relationships enable manufacturing flexibility and provide competitive advantages during market challenges and growth opportunities.

Technology Integration and Innovation

Advanced Manufacturing Capabilities

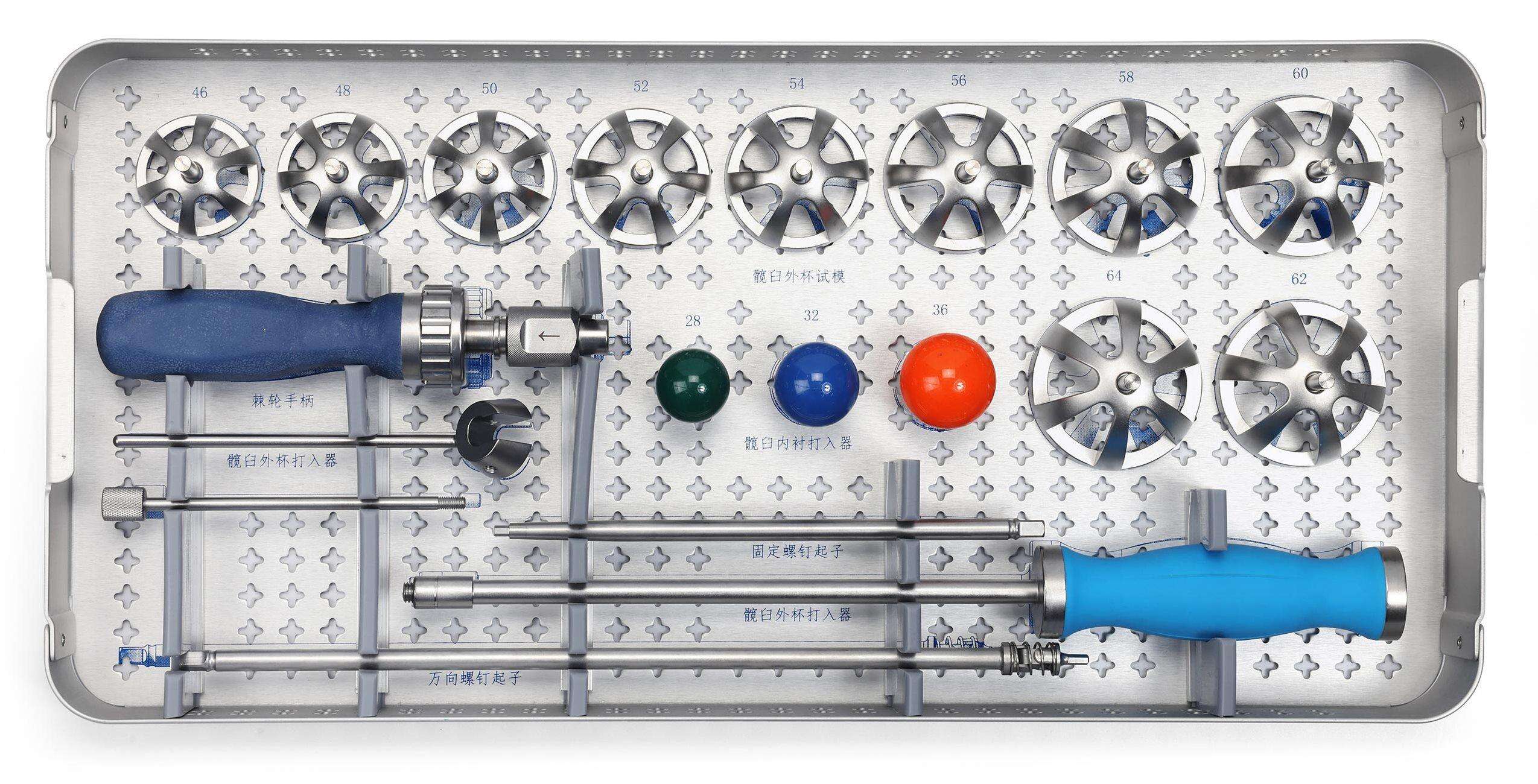

Modern orthopedic manufacturing increasingly relies on advanced technologies including additive manufacturing, robotics, and digital quality control systems. These technological investments enable improved precision, reduced costs, and enhanced product capabilities that benefit both manufacturers and customers. An orthopedic oem manufacturer who invests in cutting-edge manufacturing technologies demonstrates commitment to innovation and competitive positioning. Technology integration should focus on capabilities that improve patient outcomes, reduce costs, and enable new product development opportunities. The manufacturing partner's technology roadmap should align with industry trends and customer requirements for long-term success.

Additive manufacturing technologies have revolutionized custom orthopedic implant production and enabled new design possibilities previously impossible with traditional manufacturing methods. 3D printing capabilities for titanium, cobalt chromium, and polymer materials require significant capital investment and specialized expertise. Manufacturing partners should demonstrate proven additive manufacturing capabilities, appropriate quality control procedures, and regulatory compliance for 3D printed medical devices. These advanced capabilities enable mass customization, reduced inventory requirements, and improved patient-specific solutions that command premium pricing in the marketplace.

Digital Integration and Industry 4.0

Digital transformation in orthopedic manufacturing encompasses data analytics, predictive maintenance, and real-time quality monitoring systems that improve efficiency and reduce costs. Smart manufacturing technologies enable better decision-making, reduced waste, and improved product traceability throughout production processes. Manufacturing partners should demonstrate digital maturity through integrated manufacturing execution systems, statistical process control, and comprehensive data management capabilities. These digital investments improve manufacturing consistency, reduce quality risks, and enable proactive problem resolution before issues impact production schedules or product quality.

Cybersecurity and data protection represent critical considerations for digitally integrated manufacturing operations. Manufacturing partners must implement comprehensive cybersecurity programs to protect intellectual property, customer data, and manufacturing systems from potential threats. Data backup procedures, access controls, and incident response plans ensure business continuity and protect sensitive information. The investment in cybersecurity infrastructure and ongoing training programs demonstrates professional manufacturing capabilities and reduces risks associated with digital manufacturing technologies. These security investments protect long-term business relationships and maintain customer confidence in manufacturing partnerships.

Geographic Considerations and Market Access

Regional Manufacturing Advantages

Geographic location significantly influences manufacturing costs, regulatory compliance, and market access strategies for orthopedic device production. Domestic manufacturing provides advantages including reduced shipping costs, simplified regulatory compliance, and improved supply chain control. However, international manufacturing partnerships may offer cost advantages, specialized capabilities, or proximity to target markets that justify additional complexity. The chosen orthopedic oem manufacturer should demonstrate understanding of regional advantages and challenges that impact manufacturing decisions. Geographic diversification strategies can provide risk mitigation benefits while enabling access to specialized capabilities and cost optimization opportunities.

Regulatory harmonization efforts have simplified international manufacturing operations while maintaining stringent quality requirements across major markets. Manufacturing partners with multi-regional capabilities can provide significant advantages for companies targeting global markets. Time zone coordination, cultural understanding, and local regulatory expertise become valuable assets for international manufacturing relationships. The investment in geographically diverse manufacturing capabilities provides strategic flexibility and supports business continuity during regional disruptions or market changes. These geographic considerations should align with long-term business strategies and market expansion plans.

Logistics and Distribution Networks

Efficient logistics and distribution networks represent critical success factors for orthopedic device commercialization and customer satisfaction. Manufacturing partners should demonstrate established distribution capabilities, appropriate packaging expertise, and comprehensive shipping procedures for medical devices. Cold chain management, sterile packaging requirements, and international shipping regulations require specialized knowledge and infrastructure investments. The manufacturing partner's logistics capabilities directly impact customer satisfaction, inventory management, and market responsiveness. These distribution investments provide competitive advantages and support successful product launches in target markets.

Inventory management strategies and demand forecasting capabilities enable efficient production planning and reduced carrying costs for both manufacturers and customers. Manufacturing partners should demonstrate sophisticated inventory management systems, flexible production scheduling, and responsive customer service capabilities. These operational investments improve customer satisfaction, reduce costs, and enable rapid response to market opportunities. The integration of manufacturing and distribution operations provides synergies that benefit all stakeholders and support long-term business success in competitive orthopedic markets.

Risk Assessment and Mitigation Strategies

Quality Risk Management

Comprehensive risk management programs protect against quality failures, regulatory issues, and business disruptions that could impact patient safety and commercial success. An experienced orthopedic oem manufacturer implements proactive risk assessment procedures, mitigation strategies, and monitoring programs throughout manufacturing operations. Risk management should encompass design controls, process validation, supplier management, and post-market surveillance activities. These risk management investments provide insurance against costly quality failures and demonstrate professional manufacturing capabilities. The manufacturing partner's risk management maturity directly influences long-term business success and customer confidence.

Failure mode and effects analysis, statistical process control, and continuous monitoring programs identify potential issues before they impact product quality or customer satisfaction. Manufacturing partners should demonstrate established risk management procedures, documented mitigation strategies, and comprehensive monitoring capabilities. These risk management investments reduce quality incidents, improve regulatory compliance, and protect brand reputation in competitive markets. The proactive approach to risk management distinguishes professional manufacturers from cost-focused alternatives and provides long-term value for manufacturing partnerships.

Business Continuity Planning

Business continuity planning ensures manufacturing operations continue during unexpected disruptions including natural disasters, supply chain interruptions, and regulatory changes. Manufacturing partners should demonstrate comprehensive business continuity plans, alternative manufacturing capabilities, and disaster recovery procedures. These continuity investments protect against production delays, customer dissatisfaction, and market share loss during challenging periods. The manufacturing partner's business continuity maturity provides confidence for long-term manufacturing relationships and supports customer business planning. Regular testing and updating of business continuity plans ensures effectiveness and maintains readiness for unexpected challenges.

Financial stability and insurance coverage represent fundamental requirements for sustainable manufacturing partnerships in the orthopedic industry. Manufacturing partners should demonstrate appropriate financial resources, comprehensive insurance programs, and transparent financial reporting capabilities. These financial investments protect against business disruptions and provide confidence for long-term manufacturing commitments. The manufacturing partner's financial strength influences their ability to invest in quality systems, technology upgrades, and capacity expansion that benefit customer relationships. Due diligence regarding financial stability prevents manufacturing disruptions and protects long-term business interests.

FAQ

How do I evaluate the true cost of working with an orthopedic OEM manufacturer?

Evaluating true manufacturing costs requires comprehensive analysis beyond simple per-unit pricing. Consider tooling investments, regulatory compliance costs, quality system validation, and ongoing support requirements. Include potential costs for design changes, regulatory delays, and quality issues in your financial analysis. Request detailed cost breakdowns that include materials, labor, overhead, and profit margins to understand pricing structure. Factor in long-term costs including warranty exposure, recall potential, and relationship management expenses that extend beyond production costs.

What quality certifications should I require from an orthopedic OEM manufacturer?

Essential certifications include ISO 13485 for medical device quality management systems, FDA registration for US market access, and appropriate regional certifications for target markets. Verify current certification status and review audit reports to understand quality system maturity. Require evidence of successful regulatory submissions and ongoing compliance monitoring programs. Ensure the manufacturer maintains appropriate material supplier qualifications and demonstrates comprehensive traceability capabilities. Additional certifications for specific technologies or processes may be necessary depending on product requirements and target markets.

How can I balance cost savings with quality requirements in orthopedic manufacturing?

Successful cost-quality balance requires focusing on total cost of ownership rather than simple unit pricing. Invest in manufacturing partners who demonstrate mature quality systems and proactive risk management capabilities. Negotiate pricing structures that incentivize quality improvements and continuous cost optimization initiatives. Consider long-term partnership benefits including technology development, market expansion support, and regulatory expertise. Avoid manufacturing partnerships that compromise quality for cost savings, as quality failures typically result in much higher costs than initial savings.

What are the key risk factors when selecting an orthopedic OEM manufacturer?

Major risk factors include inadequate regulatory compliance, insufficient quality systems, and limited manufacturing capabilities. Evaluate financial stability, business continuity planning, and supply chain risk management programs. Consider geographic risks including political stability, regulatory changes, and logistics challenges. Assess technology obsolescence risks and the manufacturer's investment in capability development. Review the manufacturer's track record with similar products and their experience with regulatory submissions and post-market surveillance activities. Comprehensive risk assessment prevents costly manufacturing disruptions and quality issues.

Table of Contents

- Understanding Orthopedic OEM Manufacturing Economics

- Quality Standards and Regulatory Compliance

- Material Selection and Sourcing Strategies

- Technology Integration and Innovation

- Geographic Considerations and Market Access

- Risk Assessment and Mitigation Strategies

-

FAQ

- How do I evaluate the true cost of working with an orthopedic OEM manufacturer?

- What quality certifications should I require from an orthopedic OEM manufacturer?

- How can I balance cost savings with quality requirements in orthopedic manufacturing?

- What are the key risk factors when selecting an orthopedic OEM manufacturer?